The system is processing. Please wait a moment!

- Home Products Top 10 Beautiful, Cheap Home Elevator Models

Aluminum Glass Frame Elevator Price

| Load: | Customize |

| Speed: | 1 meter/second |

| Number of Floors: | Customize |

| Material: | Aluminum Alloy + Glass |

| Classify: | Customize |

TABLE OF CONTENTS

Machine room-less elevators are one of the most modern and advanced product lines today, designed with many outstanding advantages to meet the needs of moving in increasingly compact and optimal living spaces. This product has been receiving great trust from customers thanks to the convenience, aesthetics, and efficiency it brings. Not only that, machine room-less elevators are also highly appreciated for their ability to save installation space, reduce energy consumption and operating costs, making it an ideal choice for families who want to invest in comfort and modernity.

With a design that does not require a separate machine room, this elevator line not only helps save construction space but also minimizes complicated renovation steps, especially suitable for townhouses, renovated houses or spaces with limited area. These outstanding advantages have helped machine room-less elevators quickly become a trend that many families prioritize, contributing to improving the quality of life and adding value to the home.

Let's explore more details about the machine room-less elevator product line with Sankyo through the article below, to better understand the outstanding features, advanced technology, and benefits that this product brings. Sankyo is committed to bringing you the perfect elevator solution, meeting all requirements from aesthetics to functionality, contributing to creating a modern, comfortable and safer living space than ever.

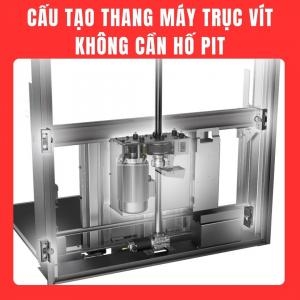

What is a machine room-less elevator?

Machine room-less elevators, also known as machine room-less elevators , are a modern solution in the field of vertical transport, designed to operate based on a traction system without the need to install a machine room above like traditional elevators. Thanks to this innovative design, machine room-less elevators have become the first choice in modern construction projects, especially high-rise buildings, townhouses, or spaces with limited area.

SEE MORE ARTICLES

This type of elevator offers outstanding convenience, not only helping to save construction space but also minimizing renovation and installation costs. For private homes, machine room-less elevators are an ideal solution, ensuring aesthetics and optimizing living space without affecting the overall architecture.

In addition, this elevator line is also highly appreciated for its operating efficiency and energy saving, with a modern engine system, smooth operation, and absolute safety. Thanks to its practical benefits and ability to meet diverse usage needs, machine room-less elevators are increasingly attracting great attention from consumers and becoming a popular trend in current construction projects.

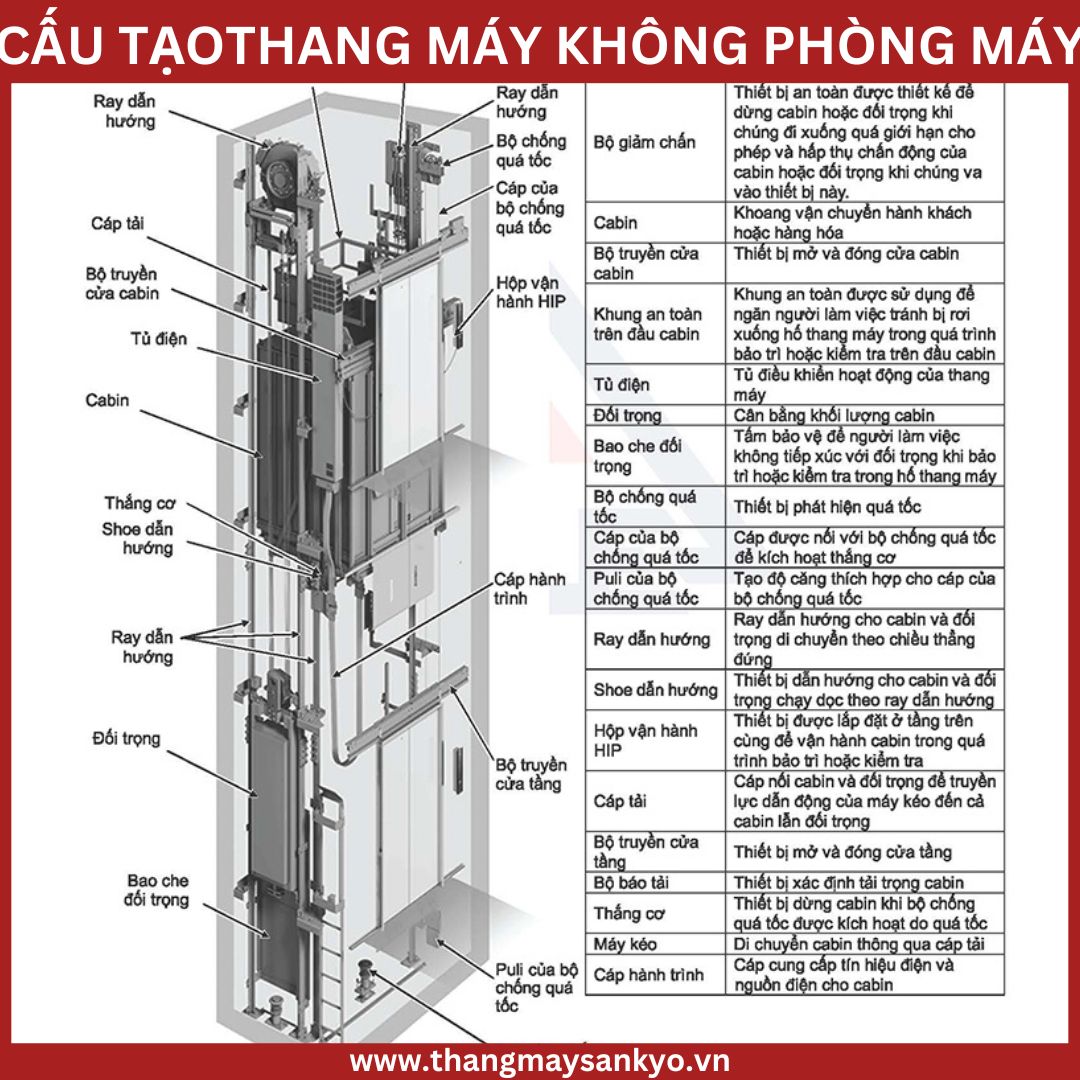

Structure of machine room-less elevator

Elevator shaft structure :

The elevator shaft structure of the machine room-less elevator is optimally designed to save space while still ensuring high operating efficiency. The special feature of this design is the use of modern gearless motors, which completely eliminates the need for a separate machine room. The gearless motor is integrated directly into the elevator shaft, helping to optimize the construction area, especially suitable for limited spaces such as townhouses or high-rise buildings.

This type of motor usually operates based on the principle of using permanent magnets combined with a control system that can flexibly adjust frequency and voltage. Thanks to that, the elevator not only operates smoothly and stably but also reduces energy consumption, contributing to saving operating costs for families or businesses.

In addition, placing the electrical cabinet in the elevator shaft also brings many benefits, from reducing installation time to optimizing the overall aesthetics of the building. Thanks to this smart structure, machine room-less elevators are increasingly becoming the top choice, meeting the needs of movement while still maintaining harmony in modern architectural design.

Shock absorber :

The elevator shock absorber is an indispensable safety device, designed to provide maximum protection in emergency situations. The main function of the shock absorber is to stop the car or counterweight when they move beyond the allowable limit during the downward travel. This helps to prevent serious incidents that may occur due to speed or force exceeding the safe level.

In addition, this device also has the ability to absorb shock when the cabin or counterweight comes into contact with the shock absorber. Thanks to that, it helps to minimize the impact and protect the safety of both the elevator system and the user. Made from special materials with high durability, the shock absorber not only ensures long-term performance but also increases stability and peace of mind during elevator operation.

With this important role, the shock absorber is one of the elements that make up the comprehensive safety system, contributing to ensuring the elevator operates smoothly and reliably, meeting modern safety standards.

Cabin :

Elevator cabins are an important part of the system, acting as a compartment for transporting passengers or goods between floors in a building. Cabins are designed in many different sizes and styles, suitable for each purpose, from families, offices, to public works or industrial zones. In addition, cabins are often made from durable materials such as stainless steel or high-grade alloys, combined with modern interiors, bringing a sense of safety and comfort to users.

In addition, the cabin door transmission plays an important role in the operation of the cabin door. This is an automatic control device that helps the door open and close smoothly and accurately, ensuring absolute safety during use. Thanks to its smart mechanism and high durability, the cabin door transmission not only helps optimize the elevator 's performance but also enhances the user's comfort and safety experience.

The perfect combination of cabin and door transmission creates a synchronous operating system, meeting daily usage needs while ensuring the highest safety standards, bringing satisfaction to users in all spaces and purposes.

Safety frame on top of cabin :

The safety frame above the cabin is an essential part of the elevator structure , designed to ensure maximum safety for those performing maintenance or inspection work during operation. This frame acts as a protective barrier, helping to prevent the risk of accidents due to slipping or falling from a high position.

The safety frame is usually made of strong and durable materials such as steel or high-grade alloy, ensuring good load-bearing capacity and stable operation in all working conditions. The design of the frame not only fits the overall structure of the elevator but is also easy to install and maintain, helping to optimize the system's operating efficiency.

Integrating a safety frame on top of the cabin is a testament to the elevator manufacturers' commitment to safety , while providing peace of mind for both users and technical staff during equipment operation and maintenance.

Electrical cabinet :

The electrical cabinet in the elevator acts as the "brain" of the entire system, where the control and management devices of the elevator are concentrated. From speed adjustment, load monitoring, to navigating the cabin to different floors, all functions are coordinated from the electrical cabinet accurately and effectively. The electrical cabinet is compactly designed but ensures all the necessary features, helping the elevator operate smoothly and safely.

In parallel, the counterweight is an indispensable device, which is responsible for balancing the cabin mass and the load inside. The counterweight is designed to reduce the load on the engine, save energy and improve operating efficiency. With the support of the counterweight, the elevator cabin can move more smoothly and stably, ensuring comfort for the user throughout the journey.

The combination of modern electrical cabinets and optimal counterweights is the key factor to help the elevator operate efficiently, safely, and save operating costs, meeting the increasing needs of consumers.

Counterweight cover:

The counterweight cover is an important part of the elevator structure, designed to ensure maximum safety for workers during maintenance or inspection of the system. It is a protective shield that prevents direct contact between the operator and the counterweight – an important moving part in the elevator shaft.

The presence of counterweight covers not only helps to minimize the risk of occupational accidents but also ensures a safe working environment, especially in confined and complex spaces such as elevator shafts. The design of counterweight covers is often optimized with durable, high-strength materials, meeting strict safety standards.

With this protective role, counterweight covers become an indispensable element in modern elevator systems , contributing to increasing safety and improving reliability during elevator operation and maintenance.

Overspeed protection :

The overspeed arrester is an important device in the elevator system, which plays a role in detecting and controlling the speed of the cabin to ensure safety during operation. This device is designed to activate the emergency brake system when it detects that the cabin is moving beyond the allowed speed, thereby preventing dangerous situations from occurring.

Overspeed arresters typically include components such as cables, pulleys, and accessories that maintain proper tension on the system's cables. Overspeed arresters are made from strong, durable materials that help ensure stable and reliable operation throughout the life of the elevator.

SEE MORE ARTICLES

The presence of an overspeed protector not only enhances safety but also meets strict technical standards in the elevator industry , providing absolute peace of mind for users. This is an indispensable factor, especially for high-rise buildings, where safety and operational efficiency are always top priorities.

Guide rails and guide shoes :

Guide rails and guide shoes are important parts of the elevator structure , playing the role of orienting the movement of the cabin and counterweight accurately and stably on the guide rail system. Guide rails are usually made of high quality steel, with good load-bearing capacity, ensuring durability and safety during operation.

The guide shoe is a supporting component, attached to the cabin and counterweight, that reduces friction and keeps the rail movements smooth and stable. The design of the guide shoe is optimized to fit a variety of rails, while minimizing noise and vibration, providing a smoother operating experience.

The combination of guide rails and guide shoes not only ensures the accuracy in orientation but also contributes to increasing the life of elevator components . This is an essential factor to meet strict technical standards, creating maximum reliability and safety for users.

HIP operating box:

HIP (Holding Control Box) is an important device installed at the top floor of the elevator, which has the function of controlling and operating the cabin during maintenance or inspection. This device helps the elevator operator to move the cabin to the required positions without having to use the conventional control system. The use of HIP (Holding Control Box) helps to increase the flexibility and convenience in checking and maintaining the elevator, while ensuring the safety of users and technicians during maintenance work.

HIP operating boxes are often designed with safety features, allowing precise and easy control of the cabin. In case of a problem or maintenance request, this device will help move the cabin to the floors or locations that need to be inspected without affecting the elevator operation . With the support of HIP operating boxes, the maintenance and inspection process becomes faster, more efficient and safer, helping to minimize downtime and increase the life of the elevator.

Cable load:

The cable is one of the core components in the elevator system, used to connect the cabin and the counterweight, and transmit the driving force from the traction machine to both components. The cable is not only responsible for ensuring that the cabin and the counterweight move in a synchronized manner, but also plays an important role in maintaining the stability and safety of the elevator during operation.

Usually made from high-strength materials, the cable is resistant to abrasion and durable against environmental and load impacts. The selection and regular maintenance of the cable is an important factor in ensuring the elevator operates efficiently, safely and has a long service life. The cable system, when operating properly, helps to optimize the balance between the cabin and the counterweight, thereby reducing the pressure on the traction motor and increasing the elevator's operating efficiency.

SEE MORE ARTICLES

Floor door transmission:

The floor door transmission is an important device in the elevator system , responsible for opening and closing the floor door accurately and safely. This device is designed to ensure perfect synchronization between the cabin door and the floor door, helping passengers move in and out of the cabin in the most convenient and safe way. The floor door transmission not only works effectively but also integrates smart features to minimize the risk of door jams or problems during operation.

Meanwhile, the load indicator acts as a cabin load monitoring device, accurately determining the weight the cabin is carrying during each trip. The load indicator not only helps ensure the cabin operates within the safe load limit but also supports warnings if the load exceeds the allowable limit, thereby protecting the elevator system and ensuring the safety of users. The combination of these two devices is an indispensable part in optimizing the performance and safety of modern elevator systems.

Win the game:

Mechanical brake is an indispensable safety device in modern elevator systems, designed to stop the cabin promptly when the overspeed protection device detects that the moving speed exceeds the allowable limit. This device operates based on an automatic activation mechanism, ensuring that the cabin does not fall into a state of loss of control, thereby protecting the safety of passengers and the elevator system . The presence of mechanical brake not only improves operational reliability but is also a key factor in minimizing the risk of accidents.

In addition, the traction machine acts as the main drive center of the elevator , responsible for moving the cabin up and down through the cable system. With a strong design and stable operation, the traction machine ensures smooth and efficient operation, meeting the needs of moving in residential buildings or high-rise buildings. The combination of mechanical brakes and traction machine creates a synchronous operating system, providing a safe, comfortable and reliable experience for users.

Travel cable

Travel cables play an important role in the elevator system, taking on the task of transmitting electrical signals and providing power to the cabin during operation. This is an indispensable part, ensuring that all cabin operations take place smoothly and accurately, from controlling the cabin door to lighting or operating the equipment inside. With a specialized design, travel cables are made from durable materials, capable of withstanding continuous movement and pressure from the environment in the elevator shaft. Thanks to the role of travel cables, the elevator system can operate stably, providing optimal safety and comfort for users.

SEE MORE ARTICLES

Reasons to use machine room-less elevators

Save installation space

One of the notable advantages of machine room-less elevators is the ability to save installation space effectively and intelligently. Instead of having to build a separate technical room to accommodate the traction system, the advanced technology of this type of elevator allows the traction machine to be integrated directly into the elevator shaft. This not only helps to optimize space but also minimizes the need for renovation and expansion of the area, especially suitable for projects with limited space such as townhouses or small buildings.

Installing a machine room-less elevator not only simplifies the construction process but also brings flexibility in design, helping architects and investors easily take advantage of every corner of the project in a reasonable way. Moreover, saving space also contributes to creating a harmonious whole between aesthetics and functionality, enhancing the aesthetic value of the house or project. With a modern and space-saving design, machine room-less elevators have become the top choice, bringing convenience, comfort and optimizing living space.

Economical and stable operation

The energy-saving and stable operation of machine-room-less elevators is one of the outstanding advantages that makes them the top choice for many projects and families. Machine-room-less elevators are equipped with gearless motors, an advanced technology from reputable manufacturers around the world. This type of motor not only has a compact design, helping to save installation space, but also ensures superior quality according to international standards when installed. The outstanding stability of gearless motors helps to minimize vibration and noise during operation, creating a smooth and comfortable user experience.

SEE MORE ARTICLES

The special feature of gearless motors is the ability to operate at lower rotation speeds than conventional motors. This not only helps to minimize vibration and mechanical noise, but also enhances the stability of the elevator, providing smooth and safe operation. Furthermore, the energy savings of gearless motors play an important role in reducing the operating costs of the elevator throughout its service life. This energy saving also means minimizing negative impacts on the environment, contributing to the protection of resources and reducing CO2 emissions.

By adopting advanced technologies and gearless motors, machine room-less elevators not only provide a cost-effective and energy-efficient solution but also ensure high safety and stability. This is the reason why machine room-less elevators are increasingly becoming the ideal choice for families and buildings that require high performance, cost savings and environmental friendliness.

Enhance aesthetics

Enhancing the aesthetics of the elevator space is an important factor that many modern homeowners care about when choosing to install an elevator in their home. One of the issues worth noting is the elevator machine room, although it plays an important role in operation, it can cause a lot of trouble and limitations in creating an aesthetic and comfortable living space.

Firstly, designing and installing the elevator machine room on the roof of the building can reduce the overall aesthetics of the house. The elevator machine room not only takes up space but can also destroy the harmony in the architecture. Having to build a large machine room on the roof not only creates a disruption in the landscape but also reduces the integration of the house with the surrounding environment. Besides, from a distance, the elevator machine room can become an unwanted view, destroying the beauty of the house.

SEE MORE ARTICLES

In addition to aesthetic issues, the construction of elevator machine rooms also faces many legal difficulties, especially in urban areas. Regulations on maximum building height are strictly applied, and adding machine room height will increase the complexity of construction licensing procedures. This is not only costly but can also cause delays in the construction process, affecting the progress and construction plan of the project.

Therefore, optimizing elevator design is not only to meet functional requirements but also to ensure aesthetics and harmony with the overall living space. Choosing a machine-room-less elevator is becoming an ideal solution to overcome these problems. With a compact design and no need for space for a machine room, a machine-room-less elevator helps to optimize the usable area and create a spacious, beautiful living space, while minimizing costs and construction procedures. This makes it easy for homeowners to own a comfortable and modern elevator space, not only meeting the needs of use but also enhancing the beauty of the house.

Save construction costs

Machine room-less elevators with the integration of gearless motors are increasingly becoming the superior choice for modern families and buildings. One of the strengths of this type of elevator is the compact design of the motor, only about 1/3 compared to elevators using geared motors. This compactness brings many benefits, not only helping to save installation space but also reducing construction costs and creating a comfortable, modern living space. With this design, you can easily install the elevator without worrying about taking up too much space, while enhancing the aesthetics of your home.

SEE MORE ARTICLES

Another outstanding advantage of machine room-less elevators is that the installation process is much simpler than traditional elevators. The installation does not require many complicated construction steps and does not require space for a separate machine room like old elevators. This not only helps reduce construction costs but also saves installation time, helping you quickly have an elevator that operates effectively without having to wait too long.

However, to ensure the quality and stability of machine room-less elevators , choosing a reputable elevator supplier and installer is very important. Experienced and professional companies will help you from consulting and choosing the right equipment for your family or project needs, to the installation and maintenance process later. Reliable suppliers will accompany you throughout the usage process, ensuring your elevator always operates stably, safely and effectively for a long time. When choosing reputable companies, you will be assured of product quality as well as after-sales service, thereby creating a modern, comfortable and safe living space for your family.

Energy saving

Machine room-less elevators are increasingly becoming a smart and efficient choice for both homes and buildings, especially in terms of energy saving, an important factor for sustainable development and environmental protection. One of the outstanding features of machine room-less elevators is the traction system using a gearless permanent magnet motor. This motor design significantly reduces power consumption compared to traditional motors, thanks to its efficiency during operation. Moreover, the compact size of the gearless motor also helps to optimize the elevator pit area, helping to save space and reduce construction costs for the project. This not only contributes to reducing operating costs for users but also reduces CO2 emissions into the environment, making a positive contribution to protecting the earth.

Another special feature of the machine room-less elevator is the advanced energy regeneration technology integrated into the system, with the Regenerative Converter. This technology works by regenerating and utilizing energy from the elevator's operation, converting excess energy during the cabin's descent into electricity and sending it back to the grid. This helps reduce up to 35% of energy consumption, contributing to reducing elevator operating costs and protecting the building's electrical system from interference currents. In addition, this technology also helps protect equipment, prolonging the life of the elevator and minimizing the risk of damage, providing sustainable performance throughout the use process.

SEE MORE ARTICLES

With outstanding advantages in energy efficiency and environmental protection, machine room-less elevators not only bring convenience and savings to users but are also a breakthrough solution in minimizing negative impacts on the environment. This is truly a smart and potential choice for modern homes and buildings, helping to save costs and optimize performance.

Safe and reliable

Safety is always the top priority for consumers when choosing an elevator, and to ensure this, advanced safety features are always integrated into modern elevator systems . One of the important features that cannot be missed in every elevator system is the emergency rescue system, especially the MELD rescue cabinet. The MELD rescue cabinet is designed to automatically operate when there is a power failure, using a backup battery to bring the elevator to the nearest floor and open the door. This helps users not to worry when they encounter a stuck elevator situation, because they can quickly escape without difficulty or danger.

In addition, the elevator door system is equipped with modern safety sensors such as HMS and MBSS, which help detect obstacles quickly and effectively. When there is an obstacle, the system will automatically hold the door open and stop, creating absolute safety for users, avoiding dangerous situations related to the elevator door suddenly closing. This is an essential feature, especially in environments with high user density or for buildings with children and the elderly.

SEE MORE ARTICLES

In addition, the Governor is also an important component that helps ensure absolute safety for passengers in the elevator. When the elevator moves over the allowed speed, the Governor will automatically intervene in the mechanical brake cable system to hold the cable system tight, and at the same time activate the mechanical brake to reduce the elevator speed. This helps control the speed and prevent dangerous situations related to the elevator moving too fast, protecting the safety of users.

Other safety features such as FER (Fire Emergency Rescue), FE (Fire Emergency Rescue), EER-P and EER-S (Earthquake Emergency Rescue) are also integrated into the elevator system . These features ensure that users can be rescued quickly and safely in special emergency situations, helping to improve the level of protection in all cases. Thanks to these safety features, the elevator not only ensures peace of mind and convenience for users but also demonstrates the strong commitment of manufacturers to protecting the health and safety of customers.

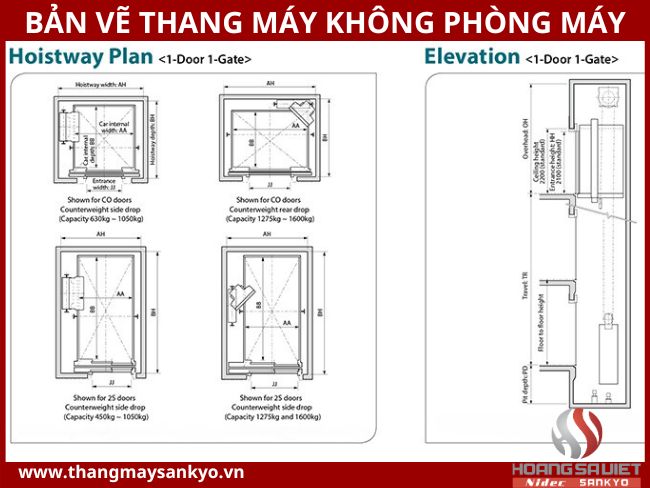

Specifications and dimensions of machine room-less elevators

Here is a detailed breakdown of the specifications and dimensions of machine room-less elevators, one of the popular choices for buildings with limited space:

Load and Number of floors:

Machine room-less elevators are an ideal solution for modern buildings, providing convenience and optimizing space. One of the outstanding advantages of this type of elevator is its flexible load capacity, from 250kg to 1000kg, or even higher, depending on the requirements and usage needs of each project. This helps machine room-less elevators meet the needs of families, residential buildings as well as commercial buildings with a variety of users and loads.

SEE MORE ARTICLES

In addition to its flexible load capacity, machine room-less elevators can also serve multiple floors in buildings. The number of floors this type of elevator can serve usually ranges from 2 to 6 floors, meeting the needs of most high-rise buildings today. However, with the development of technology, special designs can also be deployed to serve taller buildings, helping machine room-less elevators operate efficiently and safely in high-rise buildings. Thanks to its flexibility in design and good load capacity, machine room-less elevators are increasingly becoming a popular choice for modern construction projects, especially where space saving and cost optimization are required.

Movement speed:

The travel speed of a machine room-less elevator is an important factor affecting its performance and user convenience. Typically, the travel speed of a machine room-less elevator ranges from 0.2m/s to 1m/s, depending on the intended use, project requirements, and building characteristics. For buildings that require elevators in a limited space or require energy savings, slower travel speeds, such as 0.2m/s to 0.4m/s, can be selected to reduce noise and optimize operational efficiency.

On the contrary, for high-rise buildings or areas with a large number of users, the travel speed can be increased to 1m/s to increase operating efficiency and save travel time between floors. However, the choice of elevator travel speed also needs to be carefully considered, ensuring safety and comfort for users. Adjusting the speed to suit each specific need of the building will help the machine room-less elevator operate effectively, save energy and bring the best user experience to users.

Cabin and door dimensions:

The size of machine room-less elevator cabins is flexible and diverse, and can be changed according to the specific requirements of each project, from compact spaces to more spacious designs to serve high usage needs. Elevator cabins have common sizes from 0.8m x 1.0m to 1.5m x 1.5m, and in some cases, the cabin size can be larger to meet the capacity requirements or to suit the space of the project. Choosing the right cabin size is very important, because it affects the operation, usable space and aesthetic factors of the project.

In addition to the cabin size, elevator doors also have many options to ensure convenience and aesthetics. Elevator doors can be traditional opening doors or automatic sliding doors, depending on the overall design of the building and space requirements. The size of the elevator door will be calculated to match the size of the cabin, helping users to easily move in and out of the elevator conveniently, while ensuring safety and saving space for the building. Choosing the right elevator door and cabin size will bring efficiency in use and installation, while helping to optimize the cost of building and operating the elevator.

Elevator pit size:

The size of the elevator pit is an extremely important factor in the design and installation of elevators, as it ensures adequate space to accommodate necessary components such as traction machines, counterweights and other safety devices. To ensure stable and safe operation of the elevator , the size of the elevator pit must be calculated accurately and carefully, in accordance with technical requirements and safety standards. Calculating the size of the elevator pit not only involves ensuring space for the equipment but also ensuring compatibility with other elements of the building, such as accessibility for maintenance and repair, as well as the requirements for the strength of the building.

When designing the elevator pit, it is necessary to take into account the safety during use, ensuring that equipment such as the mechanical brake system, counterweight and other components can operate effectively without problems. The accurate design and calculation of the elevator pit size not only helps to improve the elevator 's operating efficiency but also minimizes unnecessary risks and incidents during use. In addition, compliance with safety regulations and standards in the design of the elevator pit also helps to ensure peace of mind for users, while supporting maintenance and periodic inspections to be carried out easily and quickly.

Engine power:

The motor of the machine room-less elevator is designed with the appropriate capacity to meet the load and speed requirements of the elevator, usually ranging from about 1.5kW to 5kW or higher depending on the specific requirements of each project. This motor capacity is selected to ensure stable and efficient operation throughout the elevator's use. With a reasonably adjusted capacity, the machine room-less elevator can operate smoothly, minimizing motor problems, while helping to save energy during operation.

SEE MORE ARTICLES

Choosing a motor with the right capacity not only ensures the elevator's operating efficiency but also helps to reduce maintenance costs and increase the life of the equipment. A low-capacity motor will save electricity, suitable for small projects and houses, while a higher-capacity motor will be used for high-rise buildings or projects that require elevator operation at higher speeds and loads. Therefore, accurately determining the motor capacity is an important factor to ensure the elevator operates safely, efficiently and saves energy for investors and users.

Safety and protection system:

Machine room-less elevators are often equipped with a series of advanced safety systems to ensure absolute safety for users in all situations. These systems include obstacle sensors that detect and stop the elevator when there is an obstacle, an emergency stop system to ensure the elevator stops immediately in an emergency, and other protective devices such as alarm or rescue systems when an incident occurs. These features not only help protect users but also enhance the reliability and peace of mind when operating the elevator, ensuring that the elevator will operate stably and safely throughout its use.

In addition to the safety systems, the specifications and dimensions of machine room-less elevators may vary depending on the manufacturer as well as the specific requirements of each project. Each project has its own conditions and requirements, so the selection of elevators must be done carefully and in detail. Before installation, it is extremely important to get accurate advice from the manufacturer or elevator design unit to ensure that all technical specifications and safety requirements are properly complied with. This helps to ensure the accuracy, efficiency and quality of the elevator project, while avoiding risks arising during the installation and operation process later.

Machine room-less elevator installation location

Machine room-less elevators, also known as machine room-less elevators, are becoming a popular choice in home construction thanks to the flexibility and convenience they bring. With modern design and integrated advanced technology, machine room-less elevators not only help save space but are also easy to install in houses with limited space. One of the outstanding advantages of this type of elevator is the convenience in the installation process, thanks to the use of advanced technology from manufacturers such as Sankyo. The elevator shaft system is designed to be integrated in a module, helping to minimize the complexity of the construction process, saving time and costs for investor

PRICE SUCCESSFUL!

PRICE UNSUCCESSFUL!

Hiện chưa có đánh giá nào về sản phẩm này!

.jpg)