The system is processing. Please wait a moment!

- Home Knowledge & Experience Sharing Experience and Knowledge About Elevators

Pocket Tips for Quickly Handling Elevator Scratches

TABLE OF CONTENTS

Elevators , with being processed from materials with high durability and good bearing capacity, inevitably have scratches after a period of use. These scratches can affect the beauty and aesthetics of the elevator. So how to fix scratches on the elevator quickly and effectively? Let's learn about the most effective methods of handling elevator scratches with Nidec SANKYO Elevator in today's article.

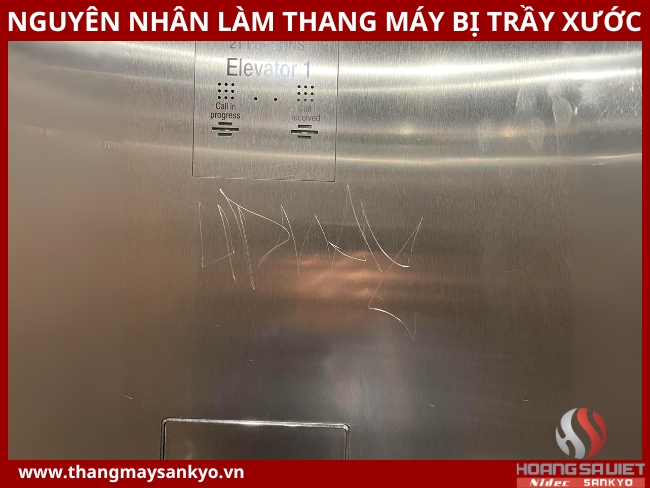

CAUSES OF SCRATCHES ON ELEVATORS

As mentioned in the introduction, although elevators are made from materials with high durability and good load-bearing capacity, the equipment can still get scratches if not cleaned and maintained properly. Scratches on elevators are often considered the most difficult to fix when dealing with surfaces, because they cause direct damage to the material and not just on the surface like stains.

Scratches on elevators can appear after a long period of use due to the impact of physical factors. Specifically, when the elevator surface comes into contact with sharp and hard metal materials such as knives and scissors, they can create scratches directly on the elevator surface.

In addition, the use of inappropriate cleaning chemicals can also cause scratches on the elevator. Chemicals with strong cleaning ingredients can corrode and scratch the elevator surface.

Not only physical and chemical impacts, external and environmental factors can also contribute to the creation of scratches on elevators. For elevators installed outdoors, exposure to sand, dust, and air over time can also cause abrasion and create scratches.

SEE MORE PRODUCTS:

COMPARISON OF SCRATCH RESISTANCE LEVEL OF ELEVATOR MATERIALS

Elevators are usually made from basic materials such as stainless steel, wood paneling, painted steel, and tempered glass. Each material has a different level of scratch resistance, details are as follows:

Wood

- Lowest scratch resistance of the four materials. This comes from the natural hardness of the wood, especially pine or birch.

- Hardwoods such as rosewood or oak are more scratch resistant, but still need to be painted with a scratch resistant coating to ensure quality.

Painted steel

- Better scratch resistance than wood due to being coated with scratch-resistant paint.

- However, the paint can peel off if not properly maintained, creating scratches on the elevator surface.

Tempered glass

- Has good scratch resistance, especially when compared to wood and painted steel.

- The surface of tempered glass can withstand pressure from 10,000 psi, and is less affected by chemical factors.

- However, excessive physical impact can scratch the glass surface over time.

Stainless steel

- Stainless steel is the material with the highest level of scratch resistance of the four materials.

- Stainless steel is often heat resistant and highly corrosion resistant, suitable for use in many different environments and is less susceptible to impact.

POCKET TIPS TO QUICKLY TREAT ELEVATOR SCRATCHES

Scratches on elevators not only cause aesthetic loss but can also affect the quality and durability of the equipment in the long run. Therefore, in addition to choosing quality materials when processing elevators, paying special attention to how to handle scratches is very important.

The methods for dealing with scratches on elevators will vary depending on the type of surface material. Let’s take a closer look at the details to get a clearer view of how to solve this problem.

Handling elevator scratches on wooden surfaces

Wooden elevator panels, although creating high aesthetic value and a cozy space for the elevator, wood is a material that is easily scratched. To solve the problem of scratches on the wooden surface of the elevator, we can apply some of the following methods:

Use walnuts

Walnuts often contain a large amount of natural oil. Using walnuts to polish wooden furniture helps bring a natural shine to the surface. This is a quick way to treat scratches on the elevator without requiring too much effort.

When using, you just need to separate the walnut kernel, then rub directly on the scratch 5-10 times until the scratch fades. Each time you rub, leave it for about 10 minutes for the walnut oil to penetrate the wood surface.

Use sandpaper to treat elevator scratches

Using torn paper is an effective method to treat deep and long scratches on the surface of wooden elevators. However, it should be noted that this treatment should only be applied to engineered wood, not to natural wood which can create deeper scratches.

First, use a piece of torn paper to rub vigorously around the scratch, following the grain of the wood. When the scratch becomes less noticeable, use a soft cotton cloth soaked in olive oil to wipe it off. Once the oil has penetrated the surface of the scratch, use paint to repaint it again.

Use beeswax, sawdust

For extremely large and highly porous scratches, you cannot simply polish them with conventional methods. In this case, the best method is to use beeswax or sawdust mixed with liquid glue to fill the hole. Then use sandpaper to smooth and carry out the color painting process, ensuring a reasonable and harmonious finish, thereby effectively covering the scratches.

.jpg)

Handling elevator scratches on painted steel surfaces

Normally, painted steel is applied with an effective waterproof and scratch-resistant paint layer. However, after a long period of use, the paint layer can be worn away if not properly maintained, leading to the steel layer underneath being exposed, creating scratches easily.

To fix scratches on the painted steel surface of the elevator , we can apply solutions such as using Ceramic coating, Graphene coating or wax. After waiting for the paint to dry, next, use sandpaper soaked in water to soften, gently wipe around the scratched area to avoid removing the paint and affecting the uniformity of the new paint layer.

Handling elevator scratches on tempered glass surface

For tempered glass material is often used to process elevators, although it has very good bearing capacity and resistance, but it is inevitable to be scratched after a long time of use. However, handling scratches on the surface of tempered glass is often quite simple and brings quick results. Below are some methods you can refer to:

Use toothpaste

To treat scratches on the elevator's tempered glass, using toothpaste is a method that many people apply and is effective, especially for small and simple scratches. Below are detailed steps to do it:

Step 1 : Use a soft cloth to clean the glass surface.

Step 2 : Pump a small amount of toothpaste onto a soft cloth. Choose a toothpaste that contains fluoride and is white.

Step 3 : Apply toothpaste directly onto the scratched tempered glass surface in a circular motion, making sure the toothpaste covers the scratch evenly.

Step 4 : Use a soft cloth to absorb the toothpaste and wipe again to remove excess toothpaste, making the glass shiny.

Use nail polish

Although it may seem simple, using nail polish to cover scratches on elevator glass is an effective and unique solution. Here are the steps to follow:

Step 1 : Clean the elevator glass surface with a soft, damp cloth, then wait for the glass to dry.

Step 2 : Use a clear nail polish brush to dab the polish onto the scratch on the glass.

Step 3 : Wait about 1 hour for the nail polish to dry completely. Then, use a little nail polish remover to apply on the scratches, creating a shine for the glass surface.

Step 4 : Use a soft, damp cloth to wipe off excess paint, creating a perfect shine for the tempered glass.

Use metal polish

For large and deep scratches on the elevator surface, using metal polishing cream is an effective solution. This method not only helps to optimally fix scratches, no matter how small or large, but also makes the surface smoother and shinier. Here is how to do it:

Step 1 : Use a candle to clearly see the scratch surface. Use a hair dryer to heat the elevator glass, helping to soften the scratch and increase the ability to absorb the polishing cream.

Step 2 : Spray the metal polish directly onto the scratched surface. Apply the cream evenly by moving the brush in a circular motion, ensuring that the cream is absorbed evenly into the glass surface. Note: Only use enough cream, avoid using too much as it can damage the glass surface.

Step 3 : Use a soft, damp cloth to gently wipe the glass surface clean. Remove excess cream, leaving a shiny and smooth layer on the elevator.

Handling elevator scratches on stainless steel surfaces

Stainless steel is the most popular material in the elevator construction process, preferred over wood, painted steel or tempered glass. The outstanding feature of stainless steel is its ability to resist scratches better than other materials. If you are having problems with scratches on the surface of the stainless steel elevator, here are some methods to handle it:

Use vinegar

Vinegar, a common kitchen ingredient, is not only used for seasoning and cooking, but can also be useful in treating scratches on the stainless steel surface of the elevator. To perform this method, you will need to prepare vinegar, water, a soft towel, cotton balls and a clean cloth. Here are the detailed steps:

Step 1 : Dissolve a small amount of vinegar in warm water.

Step 2 : Use cotton to absorb the vinegar solution.

Step 3 : Apply the soaked cotton ball to the scratch and gently brush in circular motions to fade the scratch.

Step 4 : Use a soft cloth to wipe the vinegar mixture off the scratched surface.

Step 5 : Check the results and repeat if necessary.

Note : Before applying vinegar, test on a small area to ensure that it does not affect the color or surface of the stainless steel.

Stainless steel polishing chemicals

Specialized chemicals designed specifically for polishing stainless steel often contain strong cleaning ingredients, combined with tiny particles to fill and polish scratches on the elevator surface. The process of treating elevator scratches on stainless steel is usually carried out in the following detailed steps:

Step 1 : Prepare stainless steel polishing pasta and specialized oils to brighten stainless steel.

Step 2 : Dissolve soap in warm water. Use a soft cloth soaked in the solution and gently wipe the scratched surface to remove dirt and grease.

Step 3 : Use stainless steel polishing paste on the scratched surface. Be careful to rotate in a circular motion and apply light pressure to avoid causing more scratches.

Step 4 : Wipe the stainless steel surface of the elevator with a damp cloth to create a shiny look and complete the treatment process.

Note : The circular motion and light pressure technique helps ensure that no new scratches are created during the cleaning and polishing process.

SEE MORE PRODUCTS:

SOME NOTES WHEN HANDLEING ELEVATOR SCRATCHES

With small elevator scratches, we can completely handle them ourselves with simple measures. However, to achieve the highest efficiency, we need to follow some detailed instructions as follows:

Always use soft towels

Elevator scratches often come from strong impacts such as impact force. To effectively treat scratches, the decision to use a soft cloth is important. Avoid using hard objects to avoid creating more scratches on the elevator surface. In particular, using a soft cloth helps to easily remove dirt and grease on the stainless steel surface, supporting the process of treating scratches smoothly.

Note to clean properly

When dealing with elevator scratches, the most important thing is to perform the cleaning process correctly. Always be gentle to avoid creating larger scratches on the surface. Determine the direction of the elevator surface scratches and polish in that direction, absolutely do not do it in the opposite direction to avoid increasing the severity of the scratches.

Suitable cleaning chemicals

Using the right cleaning chemicals is important when dealing with elevator scratches. Chemicals often contain acids and are corrosive, so you need to choose the right product. After use, always use a soft damp cloth to clean the scratched surface, avoiding leaving the cleaning agent on the elevator surface.

Regular maintenance

To avoid scratches on the elevator, regular maintenance is the key. Contact reputable elevator construction and maintenance units to have timely measures to handle scratches. This helps to prevent scratches from becoming serious and difficult to restore to their original condition.

Below are all the methods to fix scratches on elevators that SANKYO Elevator has collected and compiled. We hope that, with the knowledge we share, our readers have been supplemented with useful information to handle scratches that reduce the beauty of elevator models, whether in the home or business.

“Hoang Sa Viet Elevator - Always with you on every floor!”

HOANG SA VIET ELEVATOR - THE LEADING PRESTIGIOUS ELEVATOR COMPANY IN VIETNAM

Consultant: 0942.222.075 Office Headquarters: 184/20 Le Dinh Can, Tan Tao Ward, Ho Chi Minh City Hanoi Headquarters: No. 229, Van Tri Street, Van Noi, Dong Anh, Hanoi Website: thangmaysankyo.vn Email: hungpham@hoangsaviet.com

PRICE SUCCESSFUL!

PRICE UNSUCCESSFUL!

Hotline 0707.025.789

Email hungpham@hoangsa

.png)

.png)

.png)