The system is processing. Please wait a moment!

- Home Knowledge & Experience Sharing Experience and Knowledge About Elevators

Elevator Classification Criteria

TABLE OF CONTENTS

Elevators, a vertical transportation tool, have become indispensable in modern architecture today. Integrating advanced technology, elevators not only ensure absolute safety but also meet all human mobility needs. Complying with state and organization standards, modern elevators are a symbol of convenience and safety in today's society.

With a variety of designs and types, today's elevators are created to flexibly suit all types of buildings. Classifying elevators based on specific criteria helps optimize performance and integrate them effectively into any architectural project. Please join SANKYO Elevator to learn more about the criteria below!

SEE MORE PRODUCTS:

COAL CLASSIFICATIONG MACHINE BY USE

According to TCVN 7628-1:2007 standard on Elevator installation , elevators are divided into 6 types depending on the criteria of usage function. More specifically:

Passenger Lift - Passenger Lift - Type I Elevator

Passenger elevators are elevators designed to transport people in areas such as hotels, offices, motels, schools, and homes. The features of these elevators can vary widely in size, speed, and interior options, depending on the specific use of the elevator.

Freight Lift - Type II Elevator

Elevators are primarily designed to transport people, but are also optimized to handle goods that accompany the user. Often used in supermarkets, exhibition halls, factories, these passenger and goods elevators are designed to efficiently meet the needs of both people and goods movement.

Hospital elevator (patient elevator) - Type III elevator

This is an elevator specially designed to transport hospital beds (stretchers), popular in hospitals, nursing homes and medical facilities. The hospital elevator cabin is designed with spacious dimensions to conveniently accommodate both the stretcher or hospital bed, along with doctors, medical staff and related emergency equipment.

Freight elevators with people – Type IV elevators

Accompanied freight elevators are primarily designed for the transport of goods, but are often capable of carrying people. They are common in factories, workshops, warehouses and are also used in areas such as hotel staff elevators. Although primarily intended for the transport of goods, these accompanied freight elevators still provide the convenience of having a passenger to accommodate flexible mobility needs.

Unaccompanied freight elevators (service elevators) – Type V elevators

This type of unaccompanied freight elevator has the unique feature of having only the control panel outside the cabin, which is dedicated to transporting goods. The cabin of this elevator is designed with a controlled size to ensure that no one can enter inside. This elevator often appears in hotels, cafeterias or is used to transport books in libraries and meets the need for transporting goods effectively.

Special elevator - Class VI elevator

Elevators of this type have a starting speed of 2.5 m/s or more, and are often used in buildings with more than 15 floors. This helps ensure fast and efficient movement in large-scale projects.

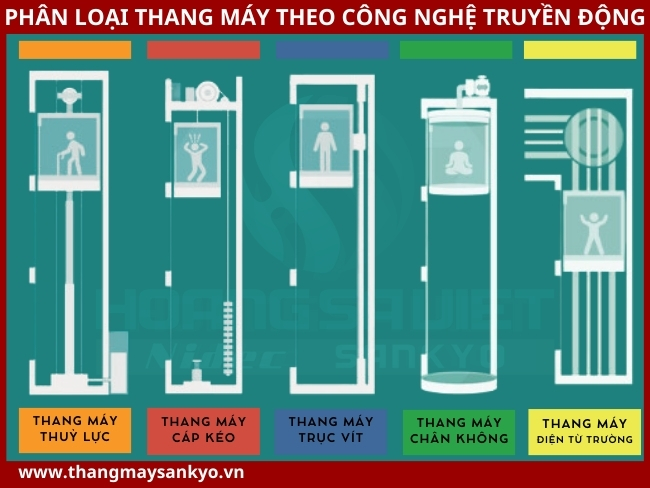

CLASSIFICATION OF ELEVATORS BY TRANSMISSION TECHNOLOGY

Elevator drive technology comparison table

|

Technology elevator |

Hydraulic Elevator |

Cable Elevator with Machine Room |

Machine room-less cable elevator |

Screw Elevator |

Vacuum Elevator |

|

Comparison criteria |

|||||

|

Optimal speed (m/s) |

0.3 - 0.6 |

≥ 1 |

0.15 - 0.3 |

0.15 |

|

|

Cabin/well area ratio |

60% |

30 - 40% |

70% |

99% |

|

|

Travel height (m) |

17 - 25 (7 floors) |

Unlimited |

2256 ≤ 16 (≤ 4 floors) |

||

|

Height OH (mm) |

2,250 - 2,600 |

3,300 (and engine room height ~ 1,800) |

2,700 - 3,400 |

2,000 |

2,400 |

|

Pit (mm) |

100 - 150 |

Minimum 600 |

Minimum 330 |

50 |

50 |

|

The smallest elevator shaft (mm) |

930 x 820 |

1200 x 1360 |

1150 x 1300 |

1020 x 980 |

|

|

Stability (dB) |

47 - 48 |

50 - 60 |

70 |

70 |

|

|

Guarantee (month) |

36 |

12 - 36 |

12 |

36 |

|

|

Advantage |

Ultra small, no noise |

Speed, height |

Space saving |

Panoramic view, space saving |

|

|

Disadvantages |

Limited speed and travel height |

Takes up space |

- Speed, stability - Travel height |

Cost, stability, ride height |

|

|

Safety features |

ARD, SRS, Emcall, CARe, SWS, SES,... |

ARD, Emcall |

ARD |

||

Note: The previous comparison table does not include electric field elevators, because this type of elevator has not yet officially appeared on the commercial market, so the missing technical parameters cannot be included.

Hydraulic elevator line

Hydraulic elevators are characterized by the cabin being pushed up from the bottom using a hydraulic cylinder. An electric pump creates pressure by pushing hydraulic fluid into the cylinder, creating enough pressure to push the piston and move the cabin. This process helps the hydraulic elevator operate safely and stably.

Hydraulic elevators today can operate with a maximum travel of about 27m, equivalent to the height of a 7-storey building. Because of the limited travel distance, they are often not suitable for buildings with too many floors.

Therefore, hydraulic elevators are often used in low-rise buildings where the height is not more than 10 floors. Hydraulic elevators are also used in low-load buildings, such as houses, hotels and restaurants…

Cable elevator line

A cable traction elevator is an advancement in elevator technology where the movement of the cabin is controlled using a single or three phase traction machine through the rotation of a pulley connected to a cable. This type of elevator is classified based on the location of the drive machine, which can be a machine room cable traction elevator or a machine roomless cable traction elevator .

A machine room cable elevator is an elevator with a separate machine room on top of the elevator shaft. The machine room is where the electrical cabinet, control cabinet, traction system and mechanical brake are located. A machine room-less elevator is an elevator without a separate machine room. The traction machine is designed on top of the cabin guide rail and counterweight. The electrical cabinet and control cabinet are located on the side of the top floor door. The mechanical brake is mounted on one side of the cabin guide rail. Two construction hooks must also be designed on the ceiling of the elevator shaft. Ventilation holes must be designed to prevent the machine from overheating.

Cable-driven elevators are commonly used in high-rise buildings, with a height of 10 floors or more. Cable-driven elevators are also used in buildings with heavy loads, such as shopping malls, hospitals, and hotels.

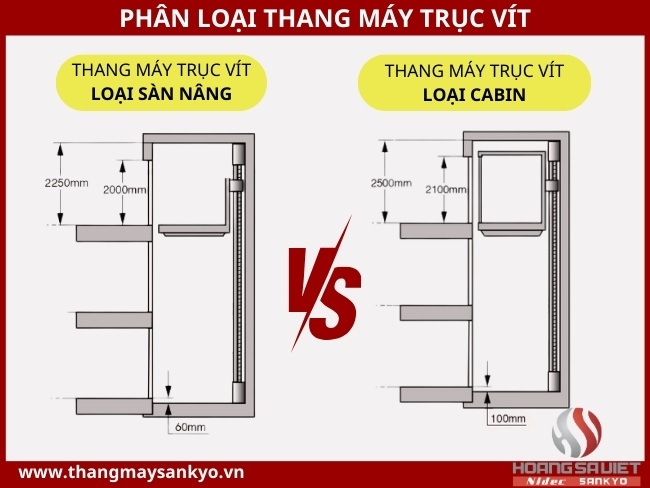

Screw elevator series

Screw elevators are a unique type of elevator that uses the screw principle to move the cabin up and down during operation. Instead of using cables or chains, screw elevators have a screw that runs vertically along the cabin and rotates to perform the movement.

However, it is also important to note that screw elevators have limited load capacities and are not suitable for high-rise or heavy-duty applications. This makes them typically used in specific situations and not the primary choice for large projects.

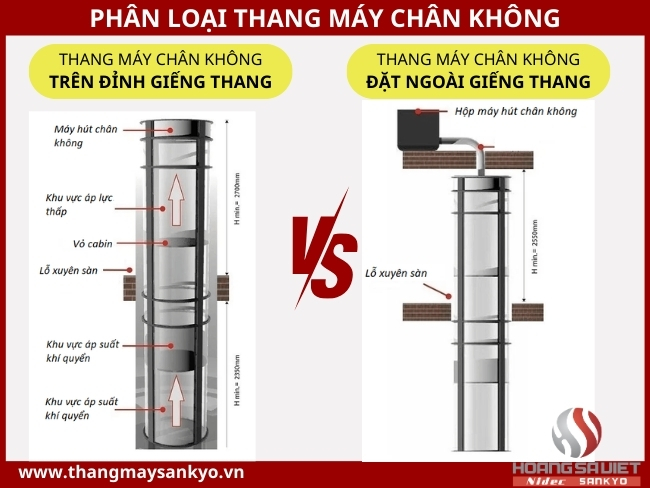

Vacuum elevator line

Vacuum elevators are unique from other elevators in their drive and structure. Their drive consists of a vacuum pump and control valves located at the top of the guide column. In the guide column, there are guide rails to shape the movement of the cabin up and down.

The roof and ceiling of the vacuum elevator cabin are discreetly designed with guide columns, which function as a kind of pneumatic piston.

This type of vacuum elevator is flexible in installation without requiring a shaft, can be placed directly on the balcony by creating a hole through the floor for the guide column to pass through. However, for practical applications, it is not popular because of the limitation in the number of stops (maximum 4 stops), low load (about 110kg to 240kg) and low travel speed.

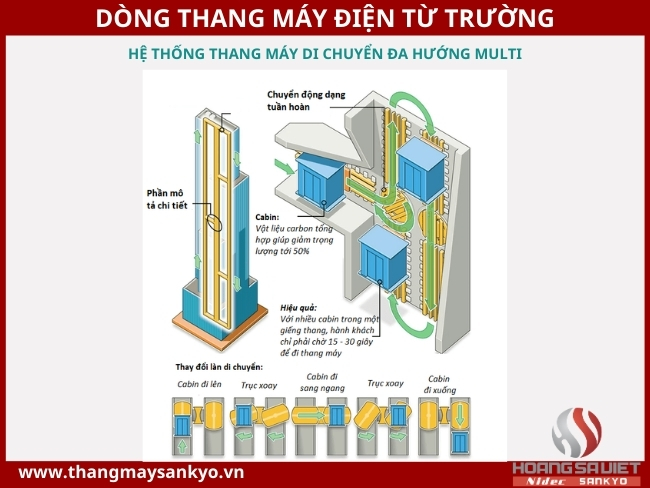

Electromagnetic elevator series

" This is the first elevator system that operates without cables, the elevator not only goes up and down but can also move left or right. This maglev elevator system can have more cabins ," said Andreas Schierenbeck , CEO of Thyssenkrupp Elevator Company .

This new electromagnetic elevator system promises to cut down a huge amount of time people spend waiting and traveling in elevators. The secret to this system lies in its ability to move without the constraints of traditional dual cables. Instead, this elevator uses a linear induction motor, built on a flat core with coils that transmit current, creating a moving magnetic field. What's special is that this motor is capable of pushing multiple different cabin systems through a single shaft, designed as a loop to flexibly move vertically, horizontally and diagonally.

The ideal height for deploying the Multi elevator system is 300m, but it is possible to use it for smaller projects. What is special is that, because the system does not use cables, it does not require the elevator compartments to be built vertically. Thanks to the ability to place multiple cabins in the same compartment, the system also helps to optimize space and reduce travel time in the building.

This new elevator model is significantly lighter than other elevators, thanks to its carbon composite structure and the complete elimination of cables. However, despite being installed on three shafts in a 246m tower in Rottweil, Germany, since 2017, the elevator has not yet been officially launched by ThyssenKrupp on the commercial market.

SEE MORE PRODUCTS:

CLASSIFICATION OF ELEVATORS BY MACHINE ROOM LOCATION

Below is a table classifying elevators according to the location of the drive machine:

|

Elevator Type |

Drive Unit Location |

|

Elevator with Machine Room (Machine Room – MR) |

- Placed at the top of the elevator shaft or next to the shaft. - Can be located on any floor in the building. - The drive machine is usually located in a separate room. |

|

Machine Room-less Elevator (Machine Roomless – MRL) |

- Place directly in the elevator shaft. - The drive machine can be above or below the bottom of the elevator shaft. - No separate computer room required. |

CLASSIFICATION OF ELEVATORS BY ORIGIN

Elevators are manufactured domestically.

According to TCVN 5744:1993 on elevators - Safety requirements in installation and use, regulations on installation conditions of domestically manufactured elevators are as follows:

1. Elevators are manufactured by legal entities and have been licensed by competent authorities.

2. Elevators must be manufactured in accordance with current technical requirements and must comply with the provisions of this standard.

3. Mass-produced elevators must be in accordance with the tested sample and must have complete original technical documents.

4. Important parts and details that cannot be manufactured must be imported or jointly manufactured. Basic parameters and technical specifications must be clearly stated in the dossier.

Domestic elevators are products registered by Vietnamese enterprises and operating in the field of elevator production and fabrication. To bring this product to the market, elevator models must meet the quality standards and current technical regulations. Important parts and details, if not yet produced domestically, must be imported or jointly manufactured, with clear basic parameters and technical specifications in the dossier.

In fact, most of the important parts such as motors, control cabinets, cables, guide rails, etc. still have to be imported, then combined with details and equipment produced by domestic enterprises.

There is a common misunderstanding that many people think that domestic elevators manufactured in the country are joint venture elevators , due to confusion in definitions and product introductions. However, these are two completely different concepts.

Joint venture elevators are products with core technology, original designs and invested in research, calculation of physical and chemical factors,... in a comprehensive way to combine details in a useful and safe way. More importantly, the connection and cooperation between the parties are built on a legal basis.

Imported elevators

According to TCVN 5744:1993 on elevators - Safety requirements in installation and use, regulations on conditions for installing imported elevators include:

1. Must have original technical documents.

2. Elevators must be manufactured according to international standards or national standards of the place of manufacture and must comply with Vietnamese safety standards.

3. The accompanying machine parts must be synchronized or if manufactured in a joint style from many manufacturers or countries, must ensure the technical specifications according to the responsible elevator manufacturer. Particularly important are the technical specifications of important parts and details such as steel cables, load-bearing chains, guide rails for the cabin and counterweight, drive pulleys, guides, correct floor control braking system, safety braking system, and safety control mechanisms, protection signals.

Imported elevators are products of international brands, imported to Vietnam in complete packages. They are manufactured according to international standards or the country of manufacture. When imported and installed in Vietnam, these elevators must comply with domestic safety standards.

According to QCVN 02:2019/BLDTBXH on Labor safety for elevators, both domestically manufactured elevators and imported elevators must be inspected and tested for safety components and equipment, including floor door locking devices and cabin door locking devices (if any), safety brakes, drive braking systems, overspeed governors, shock absorbers and shut-off valves/one-way valves.

In short, depending on the needs and specific conditions of each project, users can choose the most suitable elevator type. Elevators are designed to meet a variety of purposes and requirements, from transporting people and goods to use in special projects such as hospitals or factories. For more detailed information and free 24/7 consulting support, you can contact us immediately - SANKYO Elevator to get the fastest answers to your questions and choose the right product for your needs.

“Hoang Sa Viet Elevator - Always with you on every floor!”

HOANG SA VIET ELEVATOR - THE LEADING PRESTIGIOUS ELEVATOR COMPANY IN VIETNAM

Consultant: 0942.222.075 Office Headquarters: 184/20 Le Dinh Can, Tan Tao Ward, Ho Chi Minh City Hanoi Headquarters: No. 229, Van Tri Street, Van Noi, Dong Anh, Hanoi Website: thangmaysankyo.vn Email: hungpham@hoangsaviet.com

PRICE SUCCESSFUL!

PRICE UNSUCCESSFUL!

Hotline 0707.025.789

Email hungpham@hoangsa

.png)

.png)

.png)