The system is processing. Please wait a moment!

- Home Knowledge & Experience Sharing Experience and Knowledge About Elevators

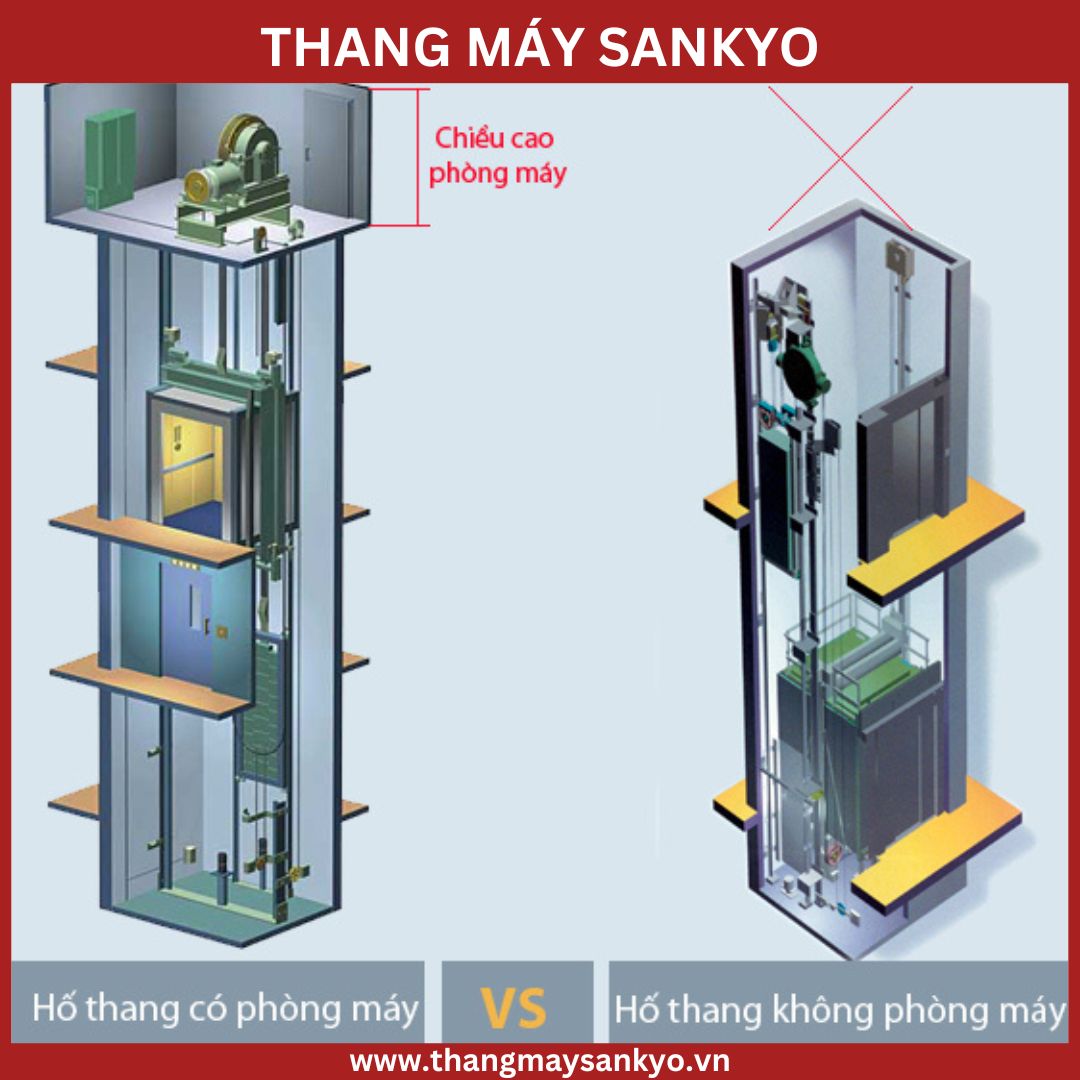

The Difference Between Machine Room Elevators and Machine Roomless Elevators

TABLE OF CONTENTS

- What is a machine room elevator?

- What is a machine roomless elevator?

- Advantages of elevators with machine rooms

- Advantages of machine room-less elevators

- Some disadvantages of elevators with machine rooms

- Some disadvantages of machine room-less elevators

- Should I choose an elevator with or without a machine room?

You are facing an important decision to install an elevator for your home, but you do not know whether to choose a machine room-less elevator or a machine room elevator that suits your needs. This is really an important decision with many factors to consider. But do not worry! Sankyo Elevator will help you answer all your questions and give you accurate advice from A to Z.

Machine room-less elevators are a modern and convenient choice for your living space. With a smart design, no need for a pit or built-in elevator shaft, this elevator will save space and construction costs for your family. You can install it in many different locations in the house without affecting the overall design.

However, if you are particularly concerned about privacy and sound, a machine room elevator may be a more suitable choice. Although it requires more space and construction costs, it offers more peace and privacy for your family.

Coming to Sankyo Elevator, you will be specifically advised on each type of elevator, from features to costs, helping you make the right decision that best suits your family's needs and finances. Let us help you make your dream of owning an elevator for your family come true!

What is a machine room elevator?

The machine room in the elevator is the area where the drive system is located, including two circuit breakers, a controller, and a pump unit. These two circuit breakers act as power sources for the equipment and disconnect the lights inside the elevator when necessary. The controller operates through a series of relays to activate the elevator's operation and is often considered the central "brain" of the system. The pump unit contains the elevator's oil and motor at the top, making it easier for technicians to control and perform routine maintenance.

Having a separate machine room makes it easier to control and maintain the elevator. Machine room elevators often need to be equipped with ventilation to increase the ability to control the internal environment, thereby minimizing the risk of damage to the equipment. In addition, installing a ceiling lift and floor hatch allows easy and convenient access to machinery and heavy components during maintenance and repair. This ensures that the elevator can operate stably and efficiently for a long time.

What is a machine room-less elevator?

Machine room-less elevator, also known as machine room-less elevator, is a type of elevator equipment specially designed with a separate machine room. The traction machine of the machine room-less elevator is usually placed on top of the cabin guide rail and counterweight, which facilitates operation and maintenance. Other equipment such as electrical cabinets and control cabinets are usually placed on the side of the top floor door.

To ensure the safety and performance of the elevator, the top of the elevator pit also needs to be specially designed. This includes the installation of two construction hooks and the design of ventilation holes to reduce the temperature of the traction machine, thereby ensuring the stable and efficient operation of the equipment.

Using machine room-less elevators not only brings convenience and safety in movement but also ensures the aesthetics and performance of the house or building. At the same time, appropriate design and installation also play an important role in optimizing space and related technical factors.

Advantages of elevators with machine rooms

The advantages of machine room elevators are something that many people notice and appreciate. The moving speed of machine room elevators is usually higher and is recommended to be greater than or equal to 1.75m/s. This is especially useful in high-rise buildings or commercial buildings with the need to transport heavy goods, exceeding 1150kg.

This feature also comes with a higher operating power of the elevator, which helps to improve the operating efficiency and the load capacity. With a transmission ratio of 1:1, the machine room elevator uses shorter cables and fewer pulleys, thereby reducing maintenance costs and ensuring the maintenance process is simple and convenient.

In addition, the rescue plan also becomes more convenient and simpler in case of power failure, even when there is no rescue team to support in time. This creates peace of mind and trust for users about the safety and convenience of elevators with machine rooms.

SEE MORE PRODUCTS:

Advantages of machine room-less elevators

One of the main advantages of machine room-less elevators is their cost-saving ability. Since they do not require installation space inside the building, they can be installed directly on the overhead hoist without the need for a separate machine room, thereby reducing the structural load and construction costs. You can save up to 70% of electricity consumption compared to hydraulic elevators, thanks to the use of frequency converters and voltage converters. This also means reduced operating costs and savings in installation costs, making machine room-less elevator quotes often lower than other types.

Machine room-less elevators do not use oil for their motors, eliminating the risk of fire and making them more environmentally friendly. You can also customize them to your specific needs with ease.

With the ability to carry 10 to 16 passengers and a load capacity of 680 to 1150 kg, machine room-less elevators meet the transportation needs of many families and buildings. The use of gearless motors is considered safe, does not cause noise and vibration. Moreover, they do not create any additional pressure on the static load of the building, helping to protect the structure and increase the safety of the moving system.

SEE MORE PRODUCTS:

Some disadvantages of elevators with machine rooms

Machine room elevators require a separate room for the traction machine, which entails the cost of building a machine room, adding to the initial cost. Compared to machine roomless elevators, machine room elevators are often much cheaper, making them a popular choice for projects with limited budgets.

However, the operating mechanism of elevators with machine rooms is often not as smooth and the energy efficiency is also lower than that of elevators without machine rooms. This makes the operating and maintenance costs of elevators with machine rooms higher in the long run.

In addition, machine room elevators also face difficulties when installed in buildings with height restrictions, as the machine room often requires a special height (usually around 2200mm). At the same time, periodic gear oil changes can pollute the environment, which is another disadvantage of this type of elevator.

On the other hand, the hoist of machine room elevators is usually smaller than that of machine roomless elevators with the same capacity. However, their energy saving ability is not as optimal as the structure of machine roomless elevators, so it is necessary to consider carefully before deciding to choose the right elevator type.

Some disadvantages of machine room-less elevators

Placing the machinery inside the elevator shaft without a machine room often brings the advantage of compact size. However, this also causes difficulties when it comes to repair and maintenance, especially when the motor has a problem. Rescue plans in case of power failure are also more difficult than in the elevator structure with a machine room.

The transmission ratio of the machine room-less elevator structure is usually 2:1, so the cable length is longer and the number of pulleys is also greater. This leads to increased maintenance and servicing costs due to the more complicated maintenance process.

Although the price of machine room-less elevators may be higher than machine room elevators, their lifespan is generally lower than other types of elevators.

When the elevator is in operation, noise is often generated due to the steel connection, which is a notable difference compared to machine room elevators.

The heat generated by machine room-less elevators can be quite large, and their heat resistance is also relatively poor. Therefore, it is necessary to ensure that the outside temperature is not too high to avoid "demagnetization", which reduces the elevator's capacity and load capacity compared to other types.

Should I choose an elevator with or without a machine room?

When deciding on the right type of elevator for your home, it is important to assess your specific needs and intended use. To help you make the right decision, here are some tips from Sankyo:

If your budget is limited, choosing an elevator with a machine room is a smart choice to save costs. Although it may be limited in terms of saving space, an elevator with a machine room still ensures basic features and conveniences for the family.

If you have a lot of money, then the machine room-less elevator will be the ideal choice. Not only does it help save installation space, the machine room-less elevator also brings convenience and modernity to the house. With advanced features, this is a valuable investment for your living space.

In case the installation space is limited in height, prioritizing the choice of machine room-less elevators will help optimize the area. This not only brings efficiency in terms of space use but also ensures the aesthetics and convenience of the house.

PRICE SUCCESSFUL!

PRICE UNSUCCESSFUL!

Hotline 0707.025.789

Email hungpham@hoangsa

.png)

.png)

.png)