The system is processing. Please wait a moment!

Compare 3 Elevator Types: Cable, Hydraulic, Screw

TABLE OF CONTENTS

Elevator technology has been making great strides, playing an important role in improving the efficiency of transporting goods and people, especially in modern buildings. Among the popular elevator lines today, hydraulic elevators, cable elevators and screw elevators are three prominent options, each with its own advantages and characteristics, providing flexibility and diversity in practical applications.

The article "Comparison of 3 types of elevators: cable, hydraulic, screw" by SANKYO Hoang Sa Viet Elevator will help you have a more general view of the rich diversity of elevator types in the transportation industry. We will learn in detail about each elevator type, analyze the differences, advantages and disadvantages to clearly see how they contribute to improving the quality of life and supporting activities in modern urbanized environments. Let's start the journey of discovery to find out why these elevator lines have become the top choice for projects from civil to commercial and industrial!

CABLE ELEVATOR?

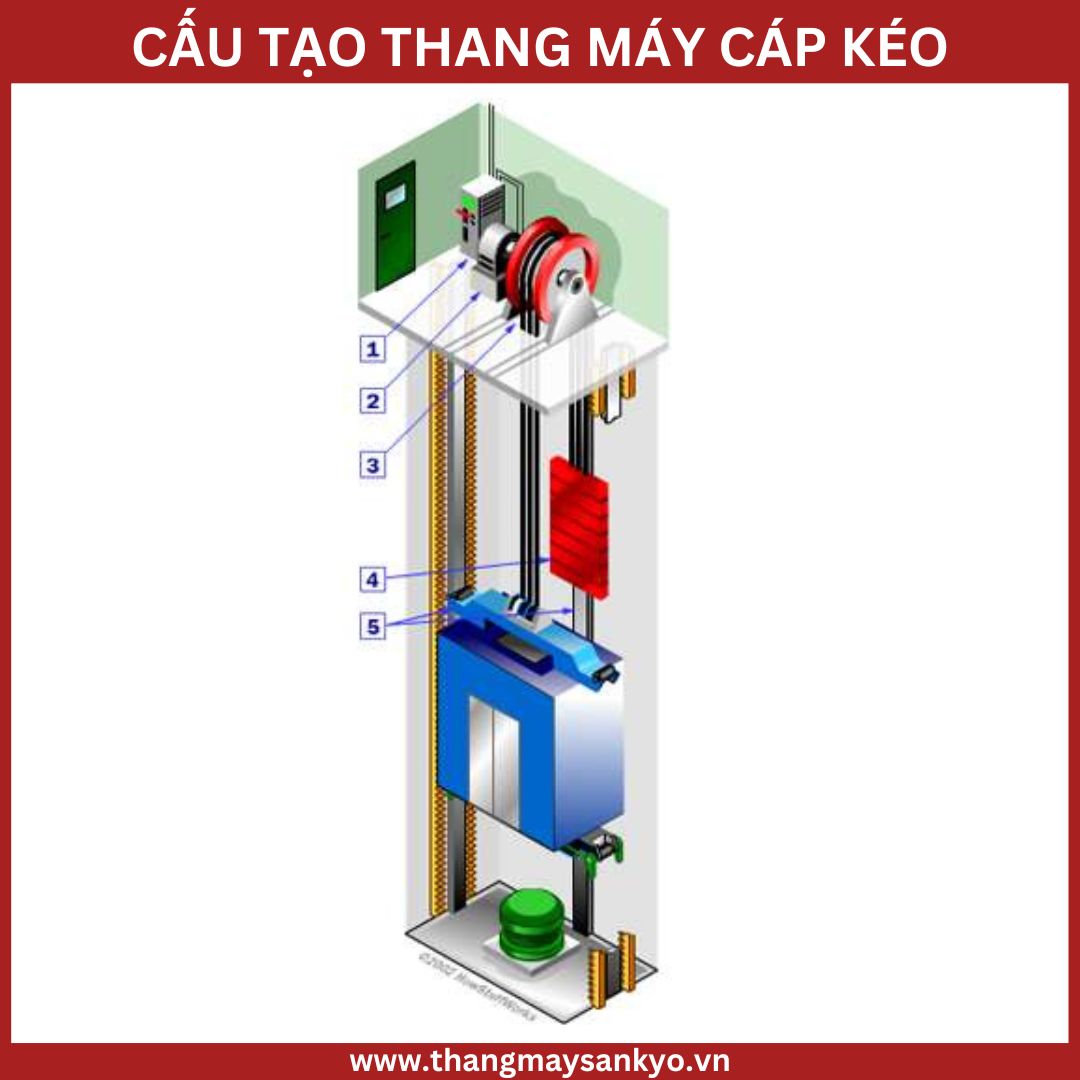

Family elevators using traction cable technology are a modern solution, providing simple but highly effective operation. The system operates based on a pulley mechanism closely linked to the electric motor. When the user selects the desired floor through the control panel, the system will immediately activate the electric current, causing the motor to start rotating. The movement of the motor simultaneously controls the pulleys to rotate, creating traction for the cabin to move up or down according to the set requirements.

SEE MORE ARTICLES

The special feature of this technology is the ability to flexibly adjust the rotation direction of the pulley and motor, suitable for the selected direction of movement. The operation process takes place smoothly and precisely, ensuring that the cabin stops at the desired floor position. Thanks to its smart design and high performance, the cable elevator not only meets the needs of daily use but also brings safety and convenience to families, especially in projects with limited installation space.

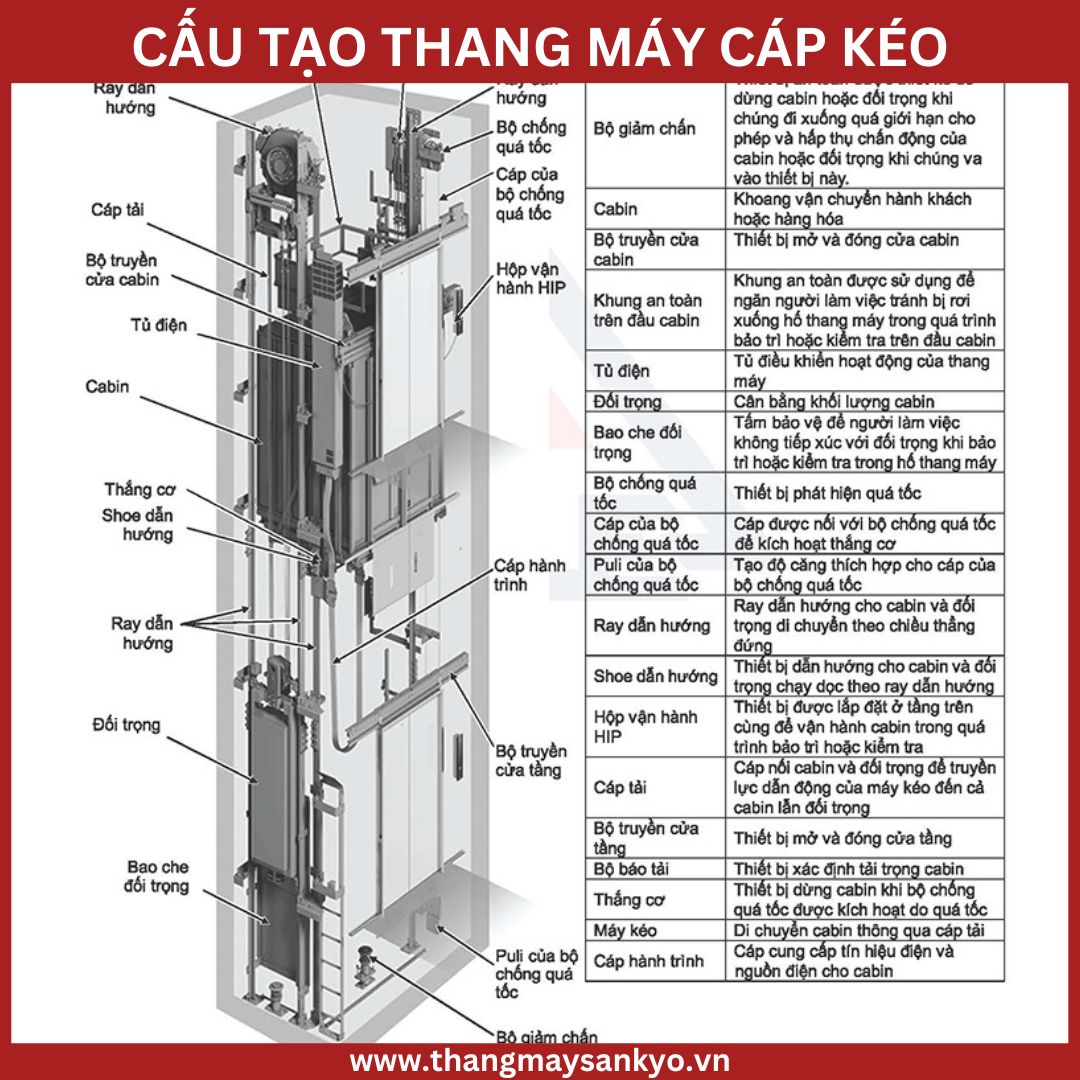

Structure of cable elevator

Elevator motor (or traction machine):

Elevator motors, also known as traction machines, play an important role in providing the necessary energy to operate the elevator system , ensuring that the cabin can move up and down stably and safely. This is the core part of the cable-driven elevator, operating based on the pulley rotation mechanism to create traction or lower the cabin as required. Currently, elevator motors are divided into two main types, including geared electric motors and new generation gearless motors.

Geared motors are commonly used in traditional elevators , featuring durable operation and suitable for large-load constructions. Meanwhile, gearless motors using modern permanent magnet technology offer many outstanding advantages. This type of motor not only helps reduce the size and weight of the device, but also optimizes performance, thereby helping the elevator move more smoothly, quietly and save energy.

In addition, the permanent magnet technology in the gearless motor also helps to reduce noise and limit vibration, providing a more comfortable user experience. With the ability to adjust movement precisely and effectively, the new generation elevator motor is becoming an increasingly popular choice, especially in home elevator projects or high-end buildings, where high performance and aesthetics are required.

Cable system

The cable system plays a central role in the operating mechanism of the traction elevator , ensuring the safe and efficient movement of the cabin. The elevator uses one or more high-quality cables, specially designed to withstand heavy loads and have high durability. These cables are connected to the cabin at one end and the other end to the counterweight via the traction machine pulley. This mechanism helps to create a balance between the cabin and the counterweight, while minimizing the energy required to operate the system.

During operation, as the cabin moves up, the counterweight moves down in the opposite direction and vice versa, helping to maintain stability and optimize traction. The cable system is designed to work in coordination with the pulley and motor, ensuring the cabin can move smoothly and accurately to the required floor.

In addition, the use of specialized cables also helps increase the safety and longevity of the elevator , minimizing wear and tear or damage during operation. The cable system is periodically maintained to ensure absolute safety, while meeting the needs of use in modern constructions. With this important role, the cable system is an indispensable factor, contributing to the efficiency and reliability of the cable elevator.

SEE MORE PRODUCTS:

Elevator cabin:

The elevator cabin is an important part, which directly serves the user's travel needs in the cable elevator system. The cabin is usually made from high-strength materials, ensuring durability and maximum safety during use. The cabin frame is usually made of sturdy steel, combined with shiny, rust-proof stainless steel walls or modern tempered glass walls, creating a feeling of spaciousness and luxury. These materials not only help the cabin withstand heavy loads but also bring aesthetic beauty, suitable for many different architectural spaces.

Cabin sizes are highly flexible, custom-designed based on specific uses. For passenger elevators, the cabin is often compact in size but still ensures a comfortable, convenient space. Meanwhile, freight elevator models often have larger cabins, with a reinforced load-bearing structure, helping to safely transport heavy objects.

In addition, the interior of the cabin is also focused on, often equipped with a modern lighting system, a cabin floor made of anti-slip materials and easy-to-use, user-friendly control buttons. The cabin is not only a place to perform the function of moving but also shows aesthetics and comfort, contributing to improving the user experience in civil and commercial works.

SEE MORE ARTICLES

Electrical cabinets and control panels:

Electrical cabinets and control panels play an important role in the operation and management of cable-driven elevators, ensuring the system operates safely, efficiently and meets the needs of users. Passenger control panels are located in many different locations, including inside the cabin, outside on floors and elevator waiting areas . These control panels are designed to be user-friendly, easy to operate with clear buttons, current floor display, floor selection button, as well as function buttons such as door opening, door closing and emergency alarm.

When passengers press the floor selection button or perform any command from the control panel, the control signal will be immediately transmitted to the central controller, the "brain" of the entire system, located in the electrical cabinet. Here, the central controller will process the signals, calculate and give precise operating commands for the elevator to move to the requested floor, while adjusting the speed, stopping position and opening the cabin door.

The electrical cabinet not only contains the central controller but also integrates other important components and devices such as converters, power supplies, safety systems, and overload protection devices. Thanks to the harmonious coordination between the electrical cabinet and the control panel, the elevator operates smoothly, ensuring maximum comfort and safety for passengers. The design and installation of the electrical cabinet and control panel are always focused on to suit the characteristics of each project, from civil houses to commercial or industrial buildings.

Safety system:

Safety system is one of the most important factors in the design and operation of cable elevators, helping to protect passengers and prevent potential incidents. To meet high safety standards, cable elevators are equipped with many modern features and technologies. One of them is the collision sensor, which is capable of detecting obstacles during the process of opening and closing the door or moving the cabin, thereby activating the emergency stop mechanism to avoid accidents.

In addition, the emergency braking system acts as an important layer of protection in the event of a sudden power failure or system failure. This system automatically activates, holds the cabin steady and prevents the cabin from moving unintentionally, ensuring the safety of passengers inside.

In addition, the safety control panel integrated into the operating system allows for quick handling of emergency situations. For example, if the cabin has a problem, passengers can use the alarm button to contact the technical team, while the central controller will activate the necessary response procedures. Thanks to these advanced safety features, the cable elevator not only brings convenience but also ensures high reliability in all usage situations.

SEE MORE PRODUCTS:

Power backup:

The power backup system plays an important role in ensuring the continuous and safe operation of the cable elevator , especially in the event of a sudden power failure. To avoid the situation of users being trapped in the cabin or the elevator stopping when the main power supply is interrupted, a backup battery system is integrated into the design.

This system provides a temporary power source, enough to complete the current journey, bring the cabin to the nearest floor and open the doors for passengers to exit safely. In addition, the backup system also ensures that important equipment such as lighting, cabin ventilation and basic control functions continue to operate for a short time, helping to minimize inconvenience and potential risks.

The use of a backup battery system not only enhances the user experience but also affirms high safety standards in modern elevator design , ensuring peace of mind and reliability in all operating conditions.

Operating principle of cable elevator

Cable elevators operate on the principle of combining electric motors, pulley systems, steel cables and counterweights. The electric motor provides rotational power to the pulley, helping to pull the steel cable to move the cabin up or down. The steel cable is wrapped around the pulley and connected to the elevator cabin with the counterweight, which acts as a gravity balancer. When the motor rotates, the cable pulls the cabin in the desired direction, while the counterweight moves in the opposite direction to balance and reduce the load on the motor. The sensor system and controller help ensure the elevator stops in the correct position, while the automatic brake keeps the cabin stable when not in use. Thanks to this principle, cable elevators provide high efficiency, save energy and ensure safety for users.

SEE MORE ARTICLES

Types of cable elevators today

Geared motor traction cable elevator

Geared elevators are a traditional elevator line designed with a separate machine room system. This type of elevator operates at a maximum speed of up to 500 feet/minute and can withstand loads of up to 13,000 kg, suitable for projects with large mass movement needs or high-rise buildings. Although the speed of geared elevators is lower than that of gearless elevators, their big advantage is that the investment cost is lower and the electric motor has a capacity that is not too large, helping to save operating costs.

Machine room cable elevators use asynchronous motors combined with a reduction mechanism for smooth operation and easy maintenance. However, this type of elevator also has certain limitations, including motor efficiency not as high as other types of elevators, large equipment mass, low transmission efficiency and high energy consumption. In addition, machine room elevators also create higher noise levels than other modern elevator lines, and sometimes the comfort during movement may not be as good as new elevator technologies. However, with reasonable investment costs and the ability to meet the needs of durable operation, geared cable elevators are still a popular choice in many projects, especially large projects where high load capacity and stable frequency of use are required.

Gearless motor traction cable elevator

Gearless cable elevators are becoming more and more popular, accounting for 70-80% of the market share, especially in mid- and high-rise buildings. This type of elevator has become the main choice in projects that require fast and efficient operation, such as passenger and freight elevators. With the ability to operate at high speeds, gearless elevators provide convenience and savings for buildings that require fast movement between floors. Unlike elevators using geared motors, gearless elevators have electric motors directly connected to pulleys, which helps reduce system complexity and improve operational efficiency.

Gearless elevator models are usually equipped with synchronous motors with simple, lightweight and high-performance structures. This type of motor has the ability to operate stably, with high torque and low speed, providing precision and durability throughout the use process. Depending on the design and application, gearless elevators can operate at speeds from 1m/s to 20m/s, serving a variety of travel needs in different projects. In particular, for family housing projects, this elevator can be adjusted to operate at low speeds from 0.6m/s to 1m/s, very suitable for apartments or houses with 4-6 floors.

Although gearless elevators have a higher initial investment, their maintenance costs are relatively low and they are energy efficient compared to conventional geared motors. Thanks to their energy savings and operational efficiency, gearless elevators are an ideal choice for high-rise and super high-rise buildings where fast travel speeds and reasonable operating costs are required.

SEE MORE PRODUCTS:

Machine room-less cable elevator (MRL)

The advent of the compact gearless motor has marked a significant step forward in improving elevator design, especially in modern buildings. In the past, traditional elevators often required a separate machine room to house the motor, but with gearless elevators , the motor can be designed and placed right on top of the elevator shaft. This design not only reduces the size and weight of the elevator system but also brings significant space savings to the building. This is the basis for the birth of the Machine Room Less (MRL) elevator line, an optimal solution for projects requiring space savings.

MRL elevators do not require a separate machine room, thus saving space in the building, while minimizing initial investment costs and installation time. The electric motors are mainly located inside the elevator shaft, optimizing system installation and maintenance. The system is also highly energy efficient and does not use oil or lubricants, thereby minimizing environmental pollution and eliminating potential fire hazards. Although MRL elevators have operating speeds comparable to traditional gearless elevator models , thanks to their simple design and energy efficiency, MRL elevators are becoming an increasingly popular choice for modern buildings, apartment buildings, or structures with limited space.

Advantages of cable elevators

Cable elevators have many outstanding advantages and are the ideal choice for many projects today. One of the biggest strengths of cable elevators is their affordable price, especially when there are many manufacturers participating in the market. Competition between manufacturers helps reduce prices, bringing significant benefits to consumers while still ensuring product quality. In addition, cable elevators also stand out with their ability to transport quickly and efficiently, helping to save time moving between floors of the building. In particular, cable elevator technology has undergone more than 200 years of development and improvement, bringing high stability and durability. With a long history and proven over time, today's cable elevators are not only reliable but also bring peace of mind to users during operation. Thanks to these advantages, cable elevators are always a popular and preferred choice in many types of projects, from high-rise buildings to commercial buildings.

Disadvantages of cable elevators

One of the main disadvantages of cable elevators is that they take up more space in the house than some other types of elevators. This comes from the structure and size of the cable elevator, which requires a free space to install the cabin, counterweight, machine room, and pit.

The need for counterweight space reduces the usable space of the cabin. In particular, to install this elevator , a pit is needed, that is, an underground space to accommodate the elevator's operating equipment. This requires the construction of a pit, creating a separate empty space under the floor. This process requires careful calculation before the house is built, and can create unexpected problems and costs if not carefully planned.

Cable elevators are suitable for which projects?

Cable traction elevators are a popular and versatile type of elevator, widely used in many types of constructions thanks to their efficient operation and space saving capabilities. Below are the constructions suitable for this type of elevator:

Residential and villas

Cable-driven elevators are widely chosen for residential buildings and villas thanks to their compact design and variety of styles. This type of elevator not only meets the need for convenient movement but also contributes to enhancing the aesthetic value of the living space. In particular, for high-end villas, luxurious glass or stainless steel cable-driven elevators are often preferred to create architectural highlights.

High-rise apartments and condominiums

High-rise apartments and condominiums often use cable-driven elevators thanks to their large load capacity, stable operation, and fast moving speed. For these buildings, the elevator system is not only a means of transportation but also a factor ensuring comfort and safety for residents.

Office Buildings

In office buildings, cable-driven elevators are widely used to meet the mobility needs of employees and customers. These buildings often require elevators with high speed, continuous operation and superior durability to suit the high frequency of use.

SEE MORE PRODUCTS:

Hotels and resorts

For hotels and resorts, cable elevators not only play a transportation role but also an element that impresses customers. This type of elevator is often designed in a modern or classic style to harmonize with the overall architecture, providing a comfortable and convenient experience for visitors.

Shopping malls and supermarkets

In shopping malls and supermarkets, heavy-duty cable-driven elevators are preferred for transporting goods and customers between floors. In particular, elevators with spacious cabins and airy designs help increase operating efficiency in crowded spaces.

Hospitals and medical facilities

In hospitals, cable elevators are used to transport patients, medical staff, and medical equipment. This type of elevator is often designed with a large cabin, smooth operation to meet specific medical requirements, ensuring safety and convenience.

Thanks to its flexible adaptability and variety of designs, cable elevators are the ideal solution for many types of projects, from residential houses to large complex buildings, meeting all needs in terms of comfort, aesthetics and operational efficiency.

SEE MORE ARTICLES

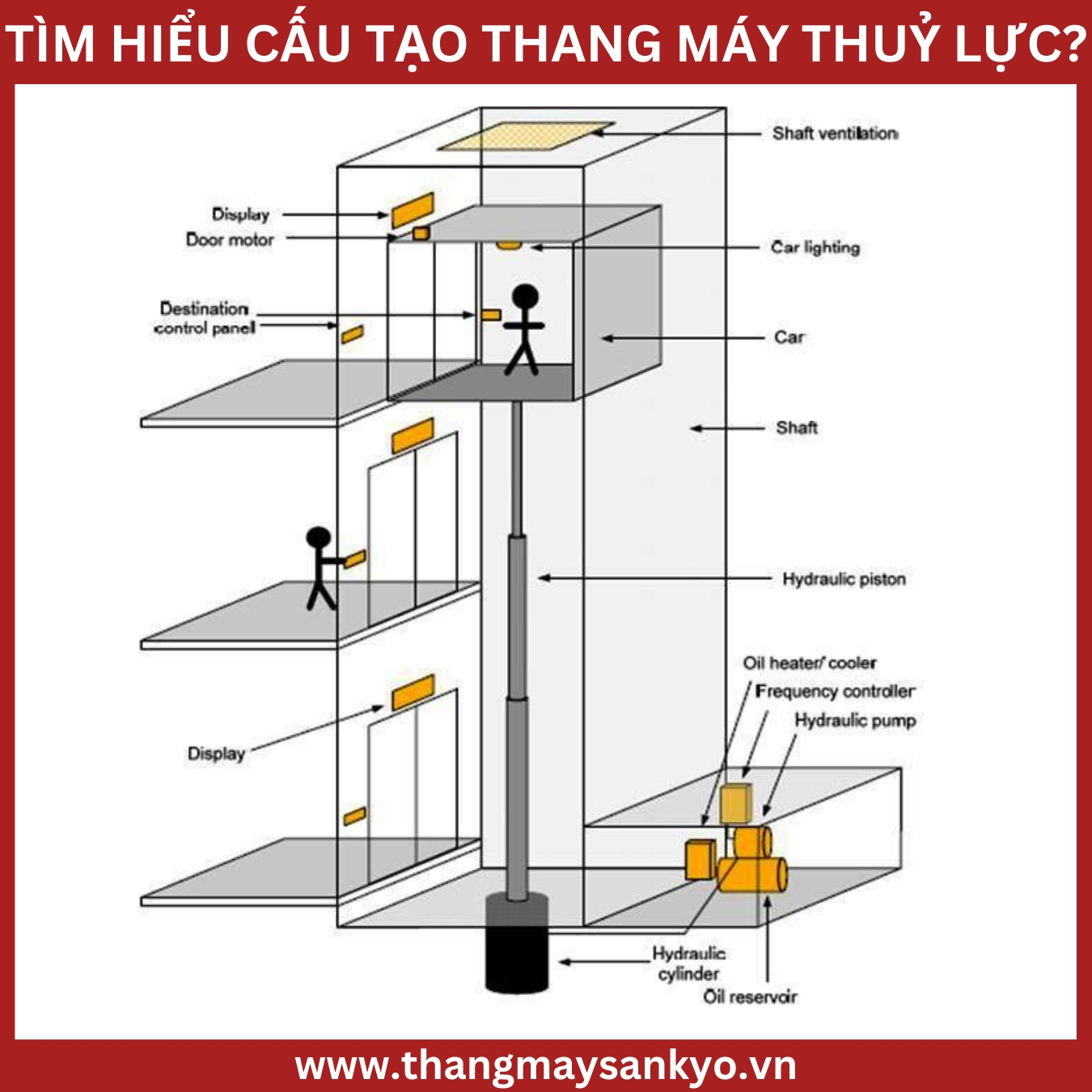

WHAT IS A HYDRAULIC ELEVATOR?

Hydraulic elevators are a type of elevator that operates based on the principle of using the pressure of oil or hydraulic fluid to move the elevator cabin. The structure of this system includes a hydraulic pump, which is responsible for pushing oil into a hydraulic cylinder. When the oil is compressed into the cylinder, the pressure from the oil will create the force for the elevator cabin to move up or down. This process takes place thanks to the change in pressure in the oil system, helping the cabin to move flexibly and stably. When the oil is released from the cylinder, the elevator cabin will lower in the opposite direction.

Hydraulic elevators are ideal for low to medium height buildings, such as low-rise buildings, single-family homes, or buildings that do not have enough space to accommodate a traditional elevator machine room. The special thing about hydraulic elevators is that they do not require a traction cable like traditional elevators, but instead are installed under the cabin or on the side of the elevator shaft. Therefore, this type of elevator is very suitable for buildings with limited space and requires quick and easy installation while still ensuring efficiency during operation. In addition, hydraulic elevators also have the advantage of saving space, requiring little maintenance, and can operate smoothly and safely even in power outages.

Structure of hydraulic elevator

Central control cabinet

The central control cabinet of the hydraulic elevator is installed outside the elevator shaft, usually on the lowest floor of the building, with a maximum distance of up to 7m from the elevator shaft. This is an important part of the hydraulic elevator system, which plays a role in ensuring that the elevator's operations take place accurately and safely. Inside the central control cabinet, there are many components that work together to ensure the smooth operation of the elevator.

One of the main parts is the motor, which operates the pump to create thrust on the hydraulic cylinder, thereby helping the elevator move up or down according to the user's request. Along with that, the hydraulic oil tank is used to store a special type of lubricating oil, which both creates pressure in the hydraulic cylinder and helps the elevator components operate smoothly and efficiently. The control system in the cabinet helps coordinate the elevator's operations, ensuring that the functions are performed accurately, from receiving user signals to performing cabin movements. Finally, the hydraulic valve system plays an important role in regulating the flow of fluid, ensuring that the hydraulic oil is directed to the necessary locations in the system, helping the elevator operate stably and efficiently. All these parts work together to ensure that the hydraulic elevator operates safely and accurately throughout its use.

Mechanical systems

The mechanical system of a hydraulic elevator plays an important role in ensuring stability and accuracy during operation. The main components of this system include the cabin frame, guide rails, guide shoes and many other details, all of which are designed to help the elevator move straight, without deviation, while maintaining balance and stability throughout the movement.

The cabin frame is the main structural part, responsible for supporting and protecting the elevator cabin, helping the cabin move safely and firmly. The guide rails and guide shoes play an important role in positioning and controlling the movement of the cabin, ensuring that the cabin moves along a certain trajectory without deviation or entanglement. Other details in the mechanical system also contribute to maintaining the stability and accuracy of the movement, while helping the elevator operate smoothly and durably. All these parts work closely together to ensure that the hydraulic elevator not only operates efficiently but is also safe for users.

Elevator shaft and cabin frame system

The elevator shaft and cabin frame system are important parts in the elevator structure, ensuring the user's movement is carried out safely and conveniently. The cabin floor door, elevator cabin and elevator shaft frame are designed and installed tightly, scientifically linked together to form a synchronous system.

Cabin doors are installed on each floor of the building, making it easy for users to get in and out of the elevator. The elevator cabin is where passengers or goods are stored during the movement between floors, designed with a sturdy and convenient structure. The elevator shaft frame, which acts as the "backbone" of the elevator system, is the main structure that helps fix and support the cabin to move up and down vertically in the elevator shaft.

SEE MORE PRODUCTS:

When these components work together, they create a smooth elevator operation process, ensuring absolute safety for users. In addition, the connection between these components also helps to limit technical problems, ensuring that the elevator will always operate efficiently and stably, while meeting the user's travel needs in all situations.

Hydraulic piston

The hydraulic piston is an important part of the hydraulic elevator system, which acts directly on the cabin to create movement up or down. The hydraulic piston has a maximum length of up to 18m, with a diameter ranging from 100mm to 200mm, helping to ensure stable and efficient operation. The hydraulic fluid pipe has a diameter of about 5mm, which is the part connected to the piston and the hydraulic oil tank, helping to lead the oil into the piston to create the necessary thrust for the elevator movement.

When oil is pumped into the cylinder, the piston will move up or down, making the elevator cabin move accordingly. The characteristic of hydraulic pistons is the ability to create very strong force, helping the elevator to operate smoothly and stably even when lifting or lowering large loads. Designed with high technical standards, hydraulic pistons ensure durability and outstanding performance throughout the use, helping the elevator operate safely and effectively in all conditions.

Working principle of hydraulic elevator

The working principle of a hydraulic elevator is based on the use of fluid pressure (usually hydraulic oil) to create thrust, helping the elevator cabin move up or down. The basic system of a hydraulic elevator includes a hydraulic pump, a hydraulic cylinder, a piston and an oil tank. When the hydraulic pump operates, it pushes oil into the cylinder, creating pressure that causes the piston to move up, pulling the elevator cabin up. When the cabin needs to be lowered, the oil is discharged from the cylinder, reducing the pressure and allowing the piston to move back, helping the cabin move down. This system does not require a traction cable like a cable elevator, but instead uses hydraulic force to control the movement, providing a space-saving and easy-to-maintain solution, suitable for low-rise buildings or buildings without space for a machine room.

SEE MORE ARTICLES

Advantages of hydraulic elevators

Hydraulic elevators offer many outstanding advantages, especially in applications that require space saving and performance optimization. One of the highlights of hydraulic elevator technology is the modernity and advancement in design and operation. Advances in the use of new components and materials, along with optimized installation and control processes, help improve operating efficiency and improve elevator safety. These improvements help reduce incidents, maintenance time, and provide a smoother and safer travel experience for users. At the same time, hydraulic elevators also help increase reliability and convenience during use.

In addition, hydraulic elevators also help save a significant amount of space, up to 80-90% compared to traditional elevators. With a neat and minimalist design, hydraulic elevators do not need counterweights and have few complicated details, thereby creating a slim and harmonious shape with the surrounding space. This is especially useful in buildings with limited space or space-saving requirements. With an installation area of only about 1m², hydraulic elevators are easily integrated into living or working spaces without taking up too much space, bringing maximum convenience to users.

Disadvantages of hydraulic elevators

- Limited installation height (usually hydraulic elevators do not make >3 floors)

- In addition, the transport speed of hydraulic elevators is often not as fast as other types of elevators, and maintenance costs may be higher due to special technical requirements.

Hydraulic elevators are suitable for which projects?

Hydraulic elevators are the ideal choice for many types of buildings, especially those that require space saving and stable performance. Below are some of the buildings where hydraulic elevators are commonly used:

Low-rise buildings and family homes : Hydraulic elevators are very suitable for low-rise buildings (usually under 5 floors), family homes, villas, or apartments with limited space. With a compact design, hydraulic elevators do not require much installation space and do not need a separate machine room, effectively saving space.

Buildings with limited space : Because they do not require counterweights and can be installed in small spaces, hydraulic elevators are very suitable for buildings that need to save space such as factories, small offices, or buildings that do not have space for a machine room.

Small commercial and service buildings : Hydraulic elevators are suitable for shops, cafes, or service areas with limited space and do not require high-speed elevators. This type of elevator provides a convenient and economical solution for buildings that need to move people or goods in small spaces.

Projects requiring smooth and stable operation : Hydraulic elevators provide smooth operation without causing loud noise, making them an ideal choice for projects such as hospitals, schools, or healthcare facilities, where quietness and stability are required during movement.

Buildings without space for a machine room : With a design that does not require a separate machine room, hydraulic elevators are a great solution for buildings without space for an elevator machine room, helping to optimize the usable area in buildings.

SEE MORE ARTICLES

Thanks to advantages such as space saving, stable performance and reasonable installation cost, hydraulic elevators are a popular choice for many different types of buildings, especially low or medium height buildings.

WHAT IS A SCREW ELEVATOR?

Screw elevators are a type of elevator that uses a screw system to move the elevator cabin up or down. Unlike traditional elevators that use traction cables or hydraulic systems, screw elevators operate based on the principle of mechanics, in which the motor rotates the screw, creating a rotating motion to pull the elevator cabin to move along the screw.

In the screw elevator system , the screw and nut are attached to the elevator cabin, and when the screw rotates, it will pull the nut to move up or down vertically. The elevator motor will control the rotation of the screw, making the cabin move smoothly and steadily.

Screw elevators are designed with a simple structure and save space, because they do not require the use of cables or hydraulic cylinders. This system is often used in buildings that are not too high in height, such as low-rise buildings, houses or buildings that require space saving. Screw elevators have the advantage of being easy to install, operate smoothly, do not require much maintenance, and are an ideal choice for small or medium-sized projects.

Structure of screw elevator

The structure of a screw elevator includes the following main parts:

Motor :

The motor is an important part of the screw elevator system, which is responsible for providing energy to rotate the screw shaft, helping to move the elevator cabin up or down. Normally, the motor of the screw elevator can be an AC electric motor, however, depending on the design and specific requirements of each system, other types of motors such as DC motors or asynchronous motors can be used. These motors are selected to suit the needs of speed, load, and performance of the elevator. The choice of motor also depends on factors such as energy consumption, operating efficiency, and maintenance costs, helping to ensure the elevator operates stably, saves energy and has a long life during use.

.jpg)

Screw :

With a characteristic spiral design, the screw shaft helps transmit rotational motion from the motor to the nut system. When the screw shaft rotates, it will pull the nut along the screw shaft, creating a pushing or pulling force, thereby helping the elevator cabin move up or down. The screw shaft is usually made from high-strength materials, such as alloy steel or high-strength metals, to ensure stable, durable operation and withstand impacts during use. In addition, the screw shaft must have high precision during the machining process to ensure performance and stability when moving. Thanks to its structure and good bearing material, the screw shaft provides smooth, precise and long-lasting operation for the elevator system.

Nut :

The nut is an important part of the screw elevator system, playing the role of directly connecting to the screw shaft to create movement for the elevator cabin. When the motor rotates, the screw shaft rotates and pulls the nut along the screw shaft. This nut is attached to the elevator cabin, helping to move the cabin up or down depending on the direction of rotation of the screw shaft. The nut is designed with high precision to ensure perfect engagement with the screw shaft, helping the elevator movement to be smooth, smooth and precise. The nut is usually made of highly wear-resistant and durable material, so that it can withstand large impact forces during long-term operation without rapid wear. In this way, the nut contributes to maintaining the performance and life of the screw elevator system , ensuring safety and stability during use.

SEE MORE PRODUCTS:

Frame :

The ladder frame is the part that bears the load and supports other parts of the elevator. Designed to ensure stability and strength, the ladder frame helps create a solid foundation for components such as the cabin, screws, nuts and other moving parts. With its load-bearing structure, the ladder frame ensures that the elevator cabin can move safely, smoothly and stably. In addition, the ladder frame must also meet the requirements of high load-bearing capacity, helping to maintain continuous operation and minimize possible incidents during use. The ladder frame is often made of durable and high-strength materials, such as stainless steel or alloy, to ensure absolute safety for the elevator. The strength and stability of the ladder frame is an important factor in maintaining the efficiency and longevity of the elevator system, while ensuring the safety of users.

Elevator cabin (Car) :

Elevator cabins serve as a moving space for passengers or goods. Designed to be attached to the nut, the cabin moves along the screw shaft as the nut moves, ensuring smooth and efficient operation. Cabins are typically sturdy in design, equipped with comfort and safety features such as automatic doors, control panels, and protective systems to ensure passenger safety. Cabin sizes can be customized to suit the needs of use, from small models for low-rise residential buildings to more spacious cabins for high-rise buildings or freight elevators. Cabin materials are also diverse, with options such as stainless steel, tempered glass, and soundproofing materials, creating a comfortable, modern, and safe moving space.

Control System :

The control system of a screw elevator consists of electronic and mechanical components, which are responsible for controlling all elevator operations, from adjusting the speed of movement to stopping at floors. This system helps ensure smooth and safe operation throughout the use process. Electronic controllers receive signals from sensors and control panels, thereby adjusting functions such as cabin speed, opening and closing of elevator doors, and warning signals. In addition, the control system also has a safety protection function, stopping the elevator when detecting incidents or problems that may affect the safety of passengers, helping the elevator to always operate stably and effectively. Modern control systems also integrate automatic technology, minimizing human intervention and helping to improve reliability throughout the use process.

SEE MORE ARTICLES

Brake System :

The brake system of the screw elevator is designed to ensure the elevator stops accurately and safely at each floor. The brake helps the cabin stop in the correct position and prevents the cabin from falling freely when the motor is not running. The brake system is manufactured with high durability, ensuring effective operation in all situations, helping the elevator operate stably and protecting the safety of passengers. This feature contributes to maintaining stability during use, even when an incident occurs.

Buffer :

The shock absorber of the screw elevator helps to minimize impact and absorb force when the cabin comes to a stop. Thanks to this part, vibration is minimized, creating smoothness and protecting other parts of the elevator from damage due to strong impacts. The shock absorber is installed at strategic locations in the elevator system, ensuring stable and durable operation of the elevator throughout the use process. This not only improves operational efficiency but also increases safety for passengers when using the elevator.

This structure helps screw elevators operate stably, save space and energy, while minimizing maintenance costs, bringing convenience an

PRICE SUCCESSFUL!

PRICE UNSUCCESSFUL!

Hotline 0707.025.789

Email hungpham@hoangsa

.png)

.png)

.png)